Spiral pipe or spiral welded steel pipe

A spiral pipe or spiral welded steel pipe is a type of steel pipe that, due to its unique structure and distinctive technical features, has found widespread use in various industries. These pipes, thanks to their unique characteristics such as high strength, long life, and pressure resistance, are an ideal choice for use in large industrial and construction projects.

History of Spiral Pipe

Content list

Spiral pipes were introduced into the industry in the 1960s and since then, due to technological advancements and the increasing needs of various industries, they have been widely used. The production of these pipes begins with steel sheets that are rolled into a spiral shape and welded at the seams.

Stages of Spiral Pipe Production

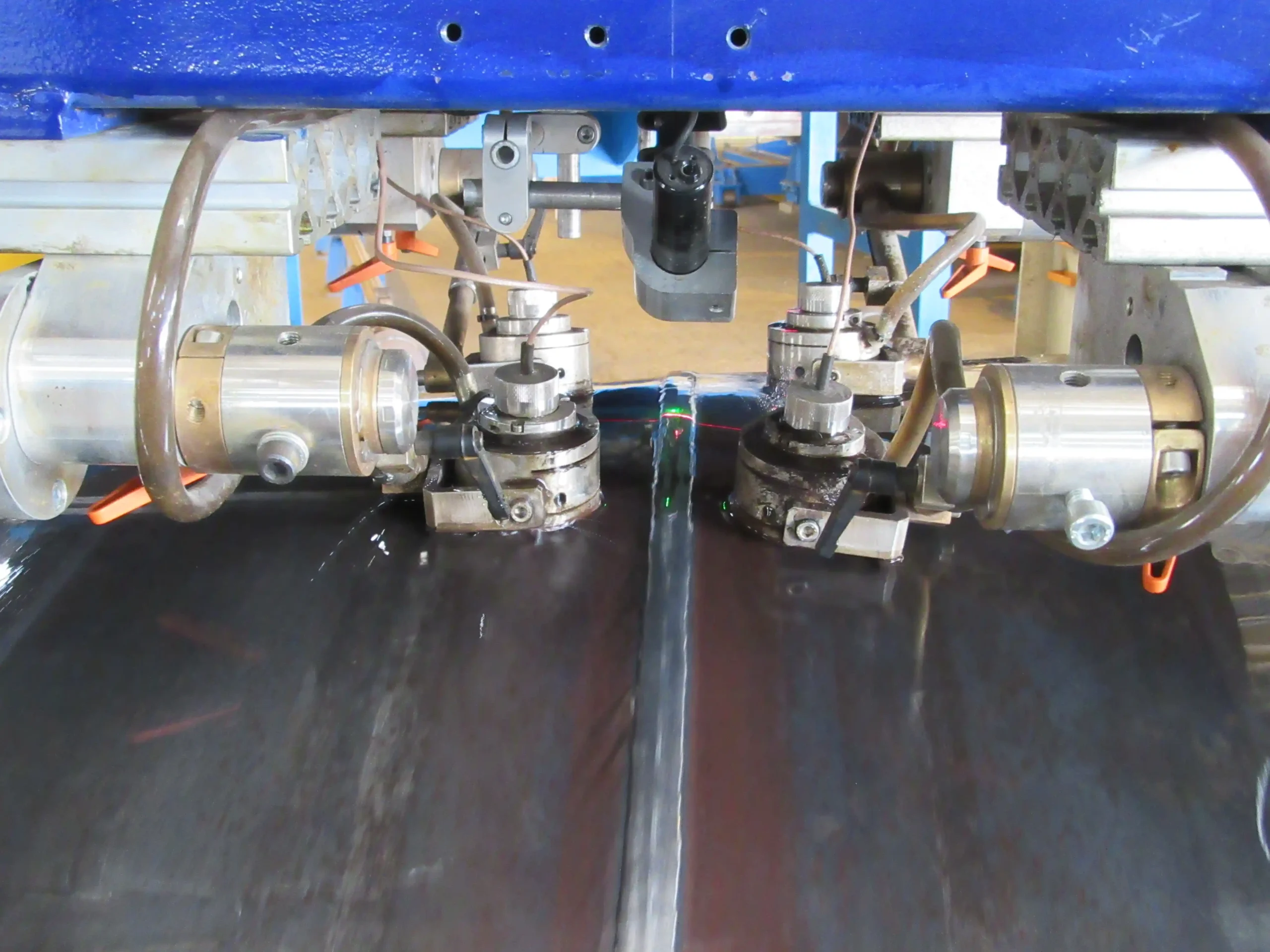

The production of spiral pipes is carried out using advanced technology and modern equipment. This process involves cutting steel sheets to the required dimensions, forming them into a spiral shape, and welding the seams using various technologies such as submerged arc welding (SAW).

- Cutting steel sheets: Steel sheets are cut to the required diameter and thickness of the pipe.

- Spiral forming: The sheets are formed into a spiral shape using special machines.

- Seam welding: The spiral seams are joined together using various welding methods to form the spiral pipe.

- Quality inspection: The produced pipes undergo rigorous quality inspections to ensure they meet the required standards.

Features of Spiral Pipe

- High Strength and Durability: Spiral pipes, due to their spiral structure and strong welded seams, have high resistance to pressures and impacts. These features make these pipes an ideal choice for use in large-scale industrial projects.

- Flexibility: One of the outstanding features of spiral pipes is their flexibility. This feature allows these pipes to be used in complex and curved paths without breaking or cracking.

Advantages and Disadvantages of Spiral Pipe

Advantages:

- High resistance to pressure and impact: Spiral pipes have a high capacity to withstand high pressures and strong impacts, making them ideal for use in harsh industrial applications.

- Long service life: Due to the high-quality materials used in their production and their strong structure, spiral pipes have a long service life, reducing maintenance and replacement costs over the long term.

- Suitable for large-scale and industrial projects: Because of their strength and durability, spiral pipes are the best choice for large-scale and industrial projects that require pipes capable of withstanding harsh conditions.

- High flexibility: Spiral pipes have high flexibility, allowing them to be installed in tight spaces and complex paths.

Disadvantages:

- Requires advanced technology: The production of spiral pipes requires the use of advanced technology and special equipment, which increases production costs.

- High production cost: Compared to some other types of pipes, the production cost of spiral pipes is higher due to the technology used and high-quality materials.

In summary, spiral pipes have a number of advantages that make them the ideal choice for many industrial applications, but the high cost of production may be a barrier to their use in some cases.

Strengths and Weaknesses of Spiral Pipes

Strengths:

- High build quality: Spiral pipes are characterized by high build quality, ensuring excellent performance and a long service life.

- Corrosion resistance: Spiral pipes are available in a variety of materials with high corrosion resistance, making them ideal for use in harsh environments.

- Easy installation and maintenance: Spiral pipes are easy to install and maintain, reducing operating costs.

Weaknesses:

- Requires regular maintenance: Spiral pipes require regular maintenance to ensure their safety and efficiency.

- Sensitivity to certain environmental conditions: Spiral pipes may be negatively affected by some harsh environmental conditions, such as extreme temperature changes or exposure to chemicals.

Tips for optimal use:

- Use high-quality connections and joints: High-quality connections and joints should be used to ensure the integrity of the pipe connections and prevent leaks.

- Regular inspection and maintenance: Regular inspection and maintenance of the pipes should be carried out to ensure that there is no damage or leakage.

- Choose the appropriate environment: The appropriate environment should be chosen for the installation of spiral pipes to avoid corrosion or damage.

Applications of spiral pipes

Spiral pipes are used in a wide range of industries and applications, including:

- Oil and gas transportation: Spiral pipes are widely used in the transportation of crude oil and gas and petroleum products.

- Water and wastewater systems: Spiral pipes are used in water and wastewater systems to ensure smooth and efficient water flow.

- Cooling systems in power plants: Spiral pipes are used in cooling systems in power plants to transfer cooling fluids.

- Construction and civil engineering projects: Spiral pipes are used in many construction and civil engineering projects, such as irrigation and sewerage systems.

In summary, spiral pipes are an excellent choice for many industrial applications due to their numerous advantages, but care must be taken to select the appropriate pipe and ensure its regular maintenance to get the most out of it.

Questions and Answers about Spiral Pipes

What is a spiral pipe? A spiral pipe or spiral welded steel pipe is a type of steel pipe produced using a spiral welding process. Due to its unique characteristics, it is used in various industries.

What are the advantages of using spiral pipes? The advantages of using spiral pipes include high resistance to pressure and impact, long life and durability, high flexibility, and ease of installation.

Where are spiral pipes used? These pipes are used in the transportation of oil and gas, water and wastewater systems, cooling systems in power plants, and construction and civil engineering projects.

What points should be considered for the maintenance of spiral pipes? Regular inspections, the use of high-quality connections and welds, and use in suitable environments are some of the points that should be considered for the maintenance of spiral pipes.

What are the disadvantages of spiral pipes? The high cost of production and the need for advanced equipment and technology for production are the disadvantages of spiral pipes.