Introduction: The Thin Line Between Rescue and Disaster

Content list

On the roads, the boundary between surviving a deadly accident or plunging off a cliff comes down to just one thing: the guardrail. This simple metal barrier, installed along the edges of busy routes, carries a heavy responsibility — saving human lives. The guardrail, or roadside fence, may appear silent and still, yet in practice, it is one of the most essential road safety devices.

Applications of Guardrails in Road and Urban Projects

Safety on Highways and Expressways

At high speeds, a vehicle leaving the roadway can be fatal. Highway guardrails prevent vehicles from veering into oncoming traffic or running off the road.Along Cliffs, Rivers, or Valleys

In areas with a risk of falling, roadside metal barriers are vital for driver safety.Separating Opposite Traffic Lanes

Using median guardrails helps reduce head-on collisions.Urban Projects and Parking Areas

In urban environments or large parking lots, roadside barriers are also used to control traffic flow and protect pedestrians.

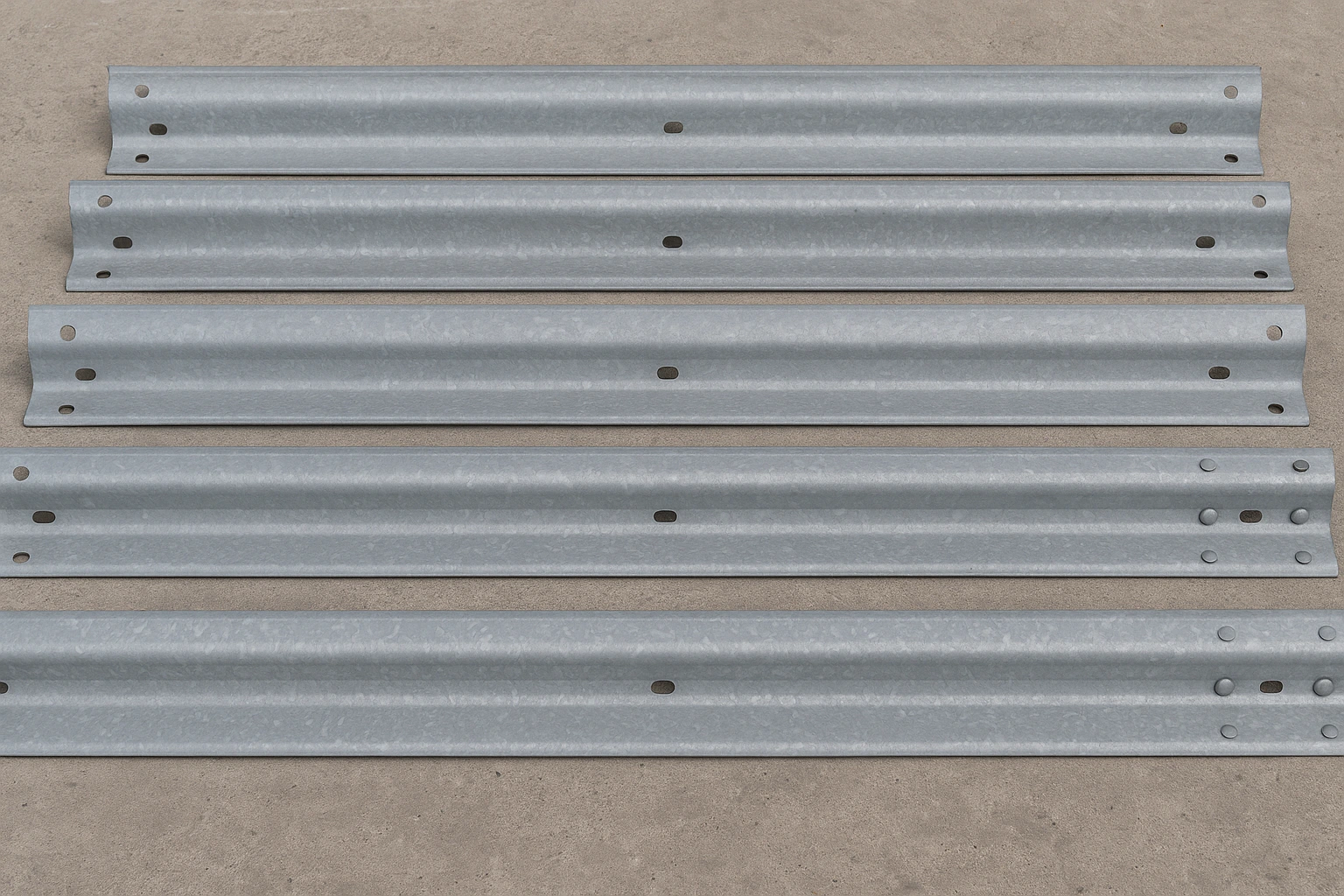

Types of Guardrails and Their Technical Specifications

| Guardrail Type | Technical Specifications | Main Application |

|---|---|---|

| Simple W-Beam Guardrail | Made of hot-dip galvanized steel sheet, 2–3 mm thick, 31 cm wide | Highways, expressways |

| Three-Wave Guardrail | Stronger and heavier, with high durability | High-traffic or hazardous routes |

| Double Guardrail | Double-layer barrier with extra strength | Bridges, mountainous areas with steep slopes |

| Flexible Guardrail | Restores shape after impact, suitable for accident-prone areas | Busy and high-risk locations |

| Decorative Urban Guardrail | Attractive design with powder coating | Streets, landscaping, parking lots |

Advantages of Standard Road Guardrails

✅ Increased road safety

✅ Reduced fatalities and property damage in accidents

✅ Prevents vehicles from falling off cliffs

✅ Separates lanes and organizes traffic flow

✅ Resistant to corrosion, moisture, and sunlight

✅ Easy to install and maintain

Guardrail Buying Guide – Key Points to Consider

- Galvanized sheet thickness: Direct impact on strength and price

- Type of joints, bolts, and nuts: Stainless steel or galvanized steel

- Surface coating: Hot-dip galvanizing or powder coating?

- Ground type at installation site: Soil, concrete, or asphalt?

- Required impact resistance: Based on the accident rate of the area

- Environmental moisture or corrosion level: Choose anti-rust models for humid or industrial zones

- Application type: Road, bridge, tunnel, urban area, or industrial site?

Guardrail Price – Factors Affecting the Cost

| Price Factor | Description |

|---|---|

| Sheet thickness | Usually between 2–3 mm; the thicker, the more expensive |

| Metal coating | Hot-dip galvanizing costs more but offers higher durability |

| Type of guardrail | Simple, three-wave, double, or flexible? |

| Number of impact absorbers | May require additional equipment such as posts and impact attenuators |

| Brand & manufacturer | Quality and service warranty affect the price |

Guardrail Installation – Steps and Execution Tips

Prepare the installation site

Install steel posts at standard intervals

Assemble and connect the guardrail sheet to posts using bolts and nuts

Install impact attenuators (if required)

Perform final stability and safety tests

Global Guardrail Standards

EN 1317: Impact resistance requirements

AASHTO M180: Road guardrail specifications

ISO 1461: Hot-dip galvanizing to prevent rust

ASTM A123: Zinc coating standard

Iran National 10225: Adaptation to Iran’s climate conditions

Mahyar Sepahan Guardrail Projects

📍 Isfahan Beltway Expressway – 5 km of three-wave guardrail

📍 Chabahar Free Zone – Anti-rust guardrail with hot-dip galvanized coating

📍 Yazd Power Plant – Industrial guardrail for route separation and facility safety

📍 Tehran Metro Parking Area – Decorative urban guardrail

Technical Specifications of Mahyar Sepahan Guardrails

| Specification | Value / Description |

|---|---|

| Sheet type | ST37 steel with hot-dip galvanized coating (ISO 1461 compliant) |

| Sheet thickness | 2, 2.5, and 3 mm (customizable per project needs) |

| Length per section | Standard 4.3 m |

| Number of waves | 2-wave or 3-wave (W-Beam / Thrie-Beam) |

| Post spacing | Standard 2 m |

| Connection type | Galvanized bolts and nuts (M16 & M20) |

| Flexibility | Available in flexible models (impact absorption capability) |

| Height from ground | Typically 70–90 cm |

| Finishing | Unpainted, hot-dip galvanized, or powder-coated |

Mahyar Sepahan Guardrail vs Other Brands

| Feature | Mahyar Sepahan | Domestic Low-Grade Brands | Unbranded Imports |

|---|---|---|---|

| International standard | Yes (EN1317 + ISO) | Mostly no | No |

| Surface coating quality | Thick galvanizing | Thin galvanizing or simple paint | Unknown |

| Actual sheet thickness | 2.5–3 mm real | Less than 2 mm | Variable |

| After-sales service | Yes | No | No |

| Price | Reasonable & negotiable | Apparently lower, but low quality | Unknown |

Common Mistakes in Buying Guardrails

❌ Ignoring the actual sheet thickness

❌ Choosing a model without impact testing

❌ Installation by a non-specialized team

❌ Using in coastal/humid areas without proper galvanization

❌ Buying from suppliers with no warranty or proven track record

Guardrails and Road Fatality Reduction — What the Statistics Say

According to the World Health Organization (WHO) and Iran’s Ministry of Roads:

Over 40% of road accident fatalities occur on intercity roads

Installing standard guardrails can reduce the likelihood of death in vehicle–obstacle collisions by up to 60%

On roads with curves and slopes, the risk of vehicle rollover without guardrails is up to 3 times higher

Therefore, a guardrail is not an expense — it’s an investment in saving lives.

Impact of Climate and Geographic Conditions on Guardrail Selection

The choice of guardrail type should match the climate and installation environment:

| Region | Features | Recommended Guardrail |

|---|---|---|

| Mountainous areas | Steep slopes, fog, icing | Three-wave or double guardrail with reinforced posts |

| Desert areas | Sandstorms, intense sunlight | Thick hot-dip galvanizing or UV-resistant powder coating |

| Coastal/Northern | High humidity and corrosion | Hot-dip galvanized guardrail with advanced anti-rust treatment |

| Industrial zones | Pollutants, gases | Chemically resistant guardrail with epoxy powder coating |

Smart Guardrails: The Future of Road Safety

The guardrail industry, like other safety equipment sectors, is entering the era of technology.

✨ Emerging Technologies in This Industry:

Impact-sensor guardrails – capable of sending alerts to traffic control centers in the event of a severe collision

Self-illuminating guardrails – using photoluminescent materials or solar power for night visibility

Flexible guardrails made of composite or durable polymers – with higher impact absorption and high rebound capability

RFID or QR code installation on guardrails – for data logging, location identification, and easier maintenance

Key Points in Guardrail Maintenance and Inspection

Like any structure, guardrails require maintenance. It is recommended to:

✅ Conduct periodic inspections of bolts, nuts, and corrosion every 6 months

✅ Replace or repair any damaged sections immediately after an accident

✅ Quickly restore damaged paint or coating to prevent rust

✅ In industrial areas, wash guardrails periodically to remove corrosive materials

✅ Use numbering and labeling for quick identification during emergency repairs

Required Documents for Guardrail Project Approval

When collaborating with government or private contractors, the following documents are essential:

Impact test certificate according to EN1317 or AASHTO standards

Product technical datasheet (Technical Sheet)

Execution drawings and installation details

Corrosion resistance approval (galvanization according to ISO 1461)

Quality guarantee (3–5 years warranty by Mahyar Sepahan)

Environmental Impact of Guardrails and Waste Management

Contrary to common belief, guardrails also have an environmental footprint:

Using recyclable steel in Mahyar Sepahan guardrails reduces the consumption of raw materials.

Standard hot-dip galvanization without lead or toxic substances is safer for nature.

Optimized packaging and transportation with Euro 5 standard trucks reduce the carbon footprint.

Why Mahyar Sepahan is the Top Choice for Road Construction Projects in Iran

Over 15 years of experience in manufacturing road safety equipment

Collaboration with municipalities, Ministry of Roads, and EPC contractors

Export quality compliant with EN and ASTM standards

Fast delivery, safe packaging, and technical support

Custom production with your project’s brand and logo

Project-Oriented Thinking: Key Points Contractors Should Know Before Purchasing Guardrails

Accurately calculate route length and post spacing — one post every 2 meters

Identify ground type (soil, concrete, asphalt) to choose base plate or foundation type

Assess vehicle speed — if over 80 km/h, three-wave guardrails are recommended

Pay attention to blind spots, curves, and danger zones — may require crash cushions or reinforced guardrails

Verify the client’s required standards — some projects only accept EN1317 or ASTM guardrails

Transparent Guardrail Price Inquiry at Mahyar Sepahan

With just a call or an online form, you can receive:

Official proforma invoice valid for 7 days

Delivery time and packaging recommendations

Shipping options based on province and project distance

Item list including guardrails, posts, bolts and nuts, crash cushions

Direct contact with a technical expert for dedicated consultation

Order Process at Mahyar Sepahan

Submit a request or make a phone call

Provide your drawings and measurements

Technical review by our engineering team

Receive proforma invoice and delivery time

Approval and advance payment

Customized production of guardrails according to specifications

Packaging, loading, and shipment with official invoice

On-site support during installation (if required)

Final Checklist for Selecting the Right Guardrail

Installation location: urban road, highway, or bridge?

Traffic speed: above 80 km/h?

Climate: humid, dry, or industrial?

Ground type: soil, asphalt, or concrete?

Required thickness: 2.5 or 3 mm?

Need for crash cushions or reinforced guardrails? Yes/No

Finish: hot-dip galvanized or powder-coated?

Our Recommendation for Project Managers and Engineers:

If you are looking for a guardrail that meets international standards, is provided by a manufacturer with a proven track record, offers installation services and professional consultation, and combines competitive pricing with export-level quality, Mahyar Sepahan will be your best choice.

Frequently Asked Questions (FAQ)

✅ What is the difference between a two-wave and a three-wave guardrail?

The three-wave model offers higher impact resistance and is suitable for high-traffic areas or locations near cliffs.

✅ Are guardrails available in specific colors?

Yes, they can be powder-coated in custom colors (yellow, white, black, etc.).

✅ Is it possible to produce custom guardrails with the logo of a municipality or specific organization?

Yes, Mahyar Sepahan offers customized production with branding services.

✅ Do you offer anti-corrosion guardrails for coastal areas?

Yes, with hot-dip galvanizing designed for humid climates.

Conclusion: Guardrails – Protection for Life

A guardrail is not just a metal barrier—it is a shield between us and disaster. With the right selection, adherence to standards, and working with a reputable manufacturer like Mahyar Sepahan, road safety can be taken to the next level.

🔧 If road, highway, or industrial project safety matters to you,

contact Mahyar Sepahan for free consultation, competitive pricing, and production tailored to your project.

📞 Phone: +98 912 118 0029

📧 Email: support@mahyarsepahan.com