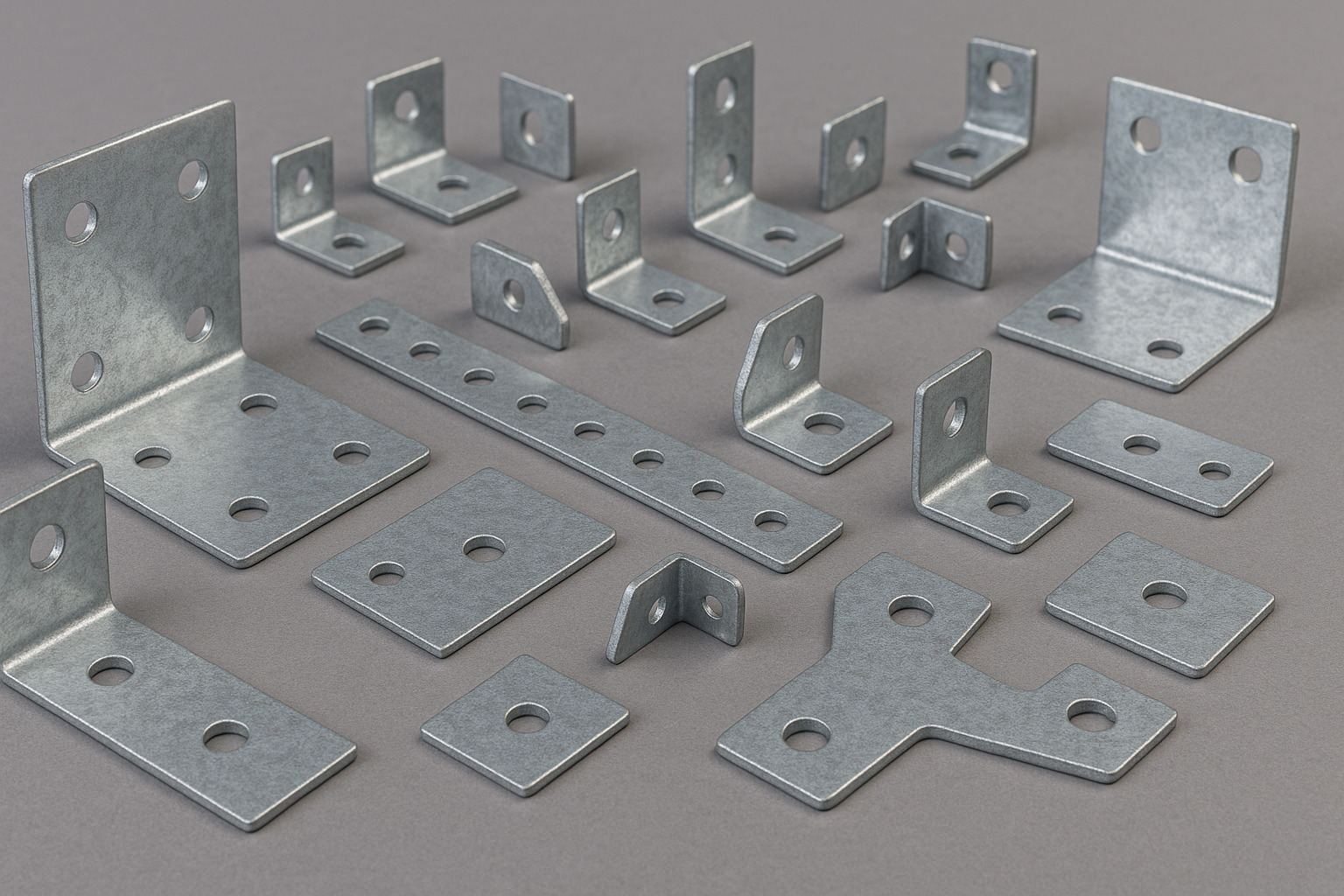

A metal bracket is a component used for connecting, supporting, or securing various parts in structures and equipment. These components are typically made from metals such as steel, aluminum, or stainless steel and are manufactured in various shapes such as L, U, Z, and T. Metal brackets are widely used in industries including construction, automotive, furniture manufacturing, and electronic equipment.

Metal Bracket: Definition and Applications

Content list

A metal bracket is a component used for connecting, supporting, or securing various parts in structures and equipment. These components are typically made of steel, aluminum, or stainless steel, and are manufactured in different shapes such as L, U, Z, and T. Metal brackets are widely used across various industries, including construction, automotive, furniture, and electronics.

Applications of Metal Brackets in Various Industries

1. Construction Industry

Equipment Installation: Metal brackets are used to mount shelves, cabinets, and pipes to walls or ceilings.

Structural Connections: Employed in the construction of steel frames, bridges, and warehouses to join structural members.

Building Facades: Provide support for cladding, decorative elements, planters, and sculptures.

2. Automotive Industry

Chassis and Body: Used to connect and secure components such as the engine, suspension, and vehicle body.

Suspension and Steering Systems: Attach various suspension and steering components to the chassis and body.

Engine and Powertrain: Secure the engine to the chassis and prevent excessive vibration or movement.

3. Furniture Industry

Furniture Assembly: Connect different parts of furniture, such as legs, backs, and shelves.

Adjustability: Some brackets allow adjustment of height, angle, or position.

4. Electrical and Electronics Industry

Mounting Electrical Panels: Fix electrical panels to walls or ceilings.

Installing Electronic Devices: Used to mount switches, sockets, and other electronic equipment.

Cable Management: Guide and protect cables and wires within buildings and equipment.

Types of Metal Brackets

L-shaped Bracket: Most common type for joining two perpendicular surfaces.

U-shaped Bracket: Designed for holding pipes and cables.

Z-shaped Bracket: Used for installing building facades and specific equipment.

T-shaped Bracket: Connects three surfaces together.

Angle Bracket: Reinforces joints in metal structures.

Manufacturing Process

Cutting and Bending: Metal sheets are cut and shaped to the desired form.

Welding: Joins multiple bracket components together.

Coating: Brackets are galvanized or powder-coated for corrosion resistance.

Advantages of Metal Brackets

High Strength: Capable of bearing heavy loads.

Durability and Long Service Life: Resistant to environmental factors.

Easy Installation: Quick and simple to use.

Design Variety: Available in various shapes and sizes.

Cost-Effective: More economical compared to alternative connection methods.

Criteria for Selecting the Right Metal Bracket

When selecting a suitable metal bracket for your project, several key factors should be considered:

Type of Application

Is the bracket intended to withstand dynamic loads or simply act as a holder? Industrial brackets designed to endure vibrations, stress, and high temperatures must be made of reinforced steel.Metal Material

Carbon Steel: Suitable for general and structural applications

Stainless Steel: Corrosion- and moisture-resistant

Aluminum: Lightweight and oxidation-resistant; ideal for electronic equipment and façade structures

Surface Coating

Hot-Dip Galvanizing: For humid and industrial environments

Electrostatic Powder Coating: For decorative or indoor projects

Chrome or Nickel Plating: For aesthetic and ornamental purposes

Drilling and Installation Standards

Ensure that the bracket’s hole pattern matches pre-defined bolts, anchor bolts, or industrial nuts precisely.

Case Studies of Metal Bracket Applications

Project 1: Solar Panel Installation on Industrial Complex Roof

Galvanized steel brackets

30° bending angle for optimal sunlight exposure

Wind load resistance up to 140 km/h

Project 2: Mounting HVAC System on Warehouse Wall

Industrial T-shaped bracket

Reinforced with additional back support to bear fan weight

Mounted with M12 anchor bolts at three fastening points

Project 3: Heavy-Duty Shelf Support in Warehouse

Double L-shaped brackets with industrial welding

Oven-cured coating for enhanced wear resistance during handling

Custom Design and Manufacturing at Mahyar Sepahan

Mahyar Sepahan offers design, manufacturing, and testing services for metal brackets according to engineering drawings or project requirements:

CAD design and CNC cutting

Hydraulic press bending

Industrial welding (CO₂ or argon)

Coating or galvanizing as per order

Load, corrosion, and adhesion tests

Industrial packaging with project labeling

Quality Control Tests for Metal Brackets

| Test | Purpose |

|---|---|

| Flexural Stress | Determine maximum load capacity |

| Tensile Strength | Ensure base connection integrity |

| Salt Spray Corrosion | Measure coating durability in humid conditions |

| Coating Adhesion | Resistance of paint or zinc to separation |

| Vibration Test | Evaluate performance under dynamic stress |

Extensive Applications of Metal Brackets in Various Industries

Below is a detailed overview of the specialized applications of metal brackets across different sectors:

Construction and Architecture Industry

Metal brackets play a crucial role in the construction and installation of modern façades, supporting canopies, billboards, and connecting lightweight structures. Custom-designed brackets enhance both the safety and aesthetics of the project.Electrical and Electronics Industry

Metal brackets are widely used for mounting electrical panels, securing galvanized pipes, holding industrial lamps, and supporting lighting systems. Brackets with thermal insulation or anti-static coatings have high value in this field.Oil, Gas, and Petrochemical Industry

In this sector, brackets must offer exceptional resistance to corrosion, heat, and chemicals. The use of stainless steel meeting ASTM or DIN standards is mandatory in their production.Automotive Industry

Reinforcement brackets are utilized in vehicle bodies, suspension systems, dashboards, and even exhaust systems. Lightweight aluminum and stainless steel brackets are vital for reducing weight while increasing strength.Military and Aerospace Industries

Brackets with high engineering precision, special alloys (such as titanium), and vibration/temperature testing are applied in these advanced fields.

Safety Tips and Installation of Metal Brackets

Proper installation ensures the long service life of a bracket. Mahyar Sepahan recommends the following safety guidelines for secure installation:

Use appropriate screws, bolts, or anchor bolts according to the wall and bracket material.

Use spring washers to prevent loosening over time.

Maintain the standard distance between brackets for balanced load distribution.

Check for the absence of rust or cracks in weld points before installation.

Avoid installing in direct contact with acid or salt without protective coating.

Export-Grade Metal Brackets with Global Quality

Mahyar Sepahan’s metal brackets are not only widely used in the Iranian market but are also exported to the Gulf region, Central Asia, and Africa. This achievement is the result of:

Using certified raw materials.

Precision manufacturing with CNC machinery.

Multi-stage quality control testing.

Professional export packaging with customer-specific labeling.

Engineering support and after-sales service in English and Arabic.

Why Mahyar Sepahan is the First Choice for Professional Projects

| Feature | Mahyar Sepahan | Generic Market Brands |

|---|---|---|

| Engineering Design | Yes – Professional CAD/CAM Team | None or Weak |

| Standard Surface Coating | Hot-dip galvanizing, powder coating, anti-acid | Simple paint or cold galvanizing |

| Cutting & Drilling Precision | CNC-level accuracy | Manual, prone to error |

| Product Variety | Over 200 types in catalog | Limited & repetitive |

| Technical Support | Engineering consultation & installation team | None |

Conclusion

Metal brackets are essential for connecting, reinforcing, and supporting various components across industries. Whether in construction, electrical systems, automotive, or industrial projects, the right bracket can:

Increase system lifespan

Enhance safety

Simplify equipment installation

Improve structure aesthetics and organization

By choosing engineered, tested, and galvanized brackets from Mahyar Sepahan, your project will not only be safer but also more economical and compliant with standards.

Frequently Asked Questions (FAQ)

Which is better: galvanized or painted brackets?

Galvanized brackets offer higher resistance to moisture and corrosion, making them ideal for outdoor or humid environments. Painted brackets are more suitable for indoor or decorative applications.Can a metal bracket withstand dynamic loads?

Yes, if it is industrially designed with proper material and thickness. Mahyar Sepahan also produces brackets tested for vibration and impact.Can you manufacture brackets based on customer drawings?

Yes, Mahyar Sepahan offers design, manufacturing, and testing based on your specific dimensions and project needs.What is the maximum load capacity of industrial brackets?

Depending on the type and sheet thickness, some industrial brackets can easily withstand several hundred kilograms of static load.How long does hot-dip galvanizing protect against rust?

Under standard conditions, hot-dip galvanizing can protect against rust for up to 30 years.

Contact Mahyar Sepahan

📧 Email: support@mahyarsepahan.com

📱 WhatsApp Quick Consultation: +98 912 118 0029