Modular Formwork is a type of metal or composite formwork system used for concrete casting in construction and civil engineering projects. These formworks are manufactured in standard dimensions with interconnectable components, allowing for fast and highly accurate assembly and dismantling.

Key Features of Modular Formwork

Content list

Modularity (Interconnectable Design): Ability to connect multiple panels of different dimensions to create various form shapes.

Robust Metal Structure: Typically made of 3 mm steel sheets with reinforced ribs.

Durable Surface Coating: Hot-dip galvanizing or powder coating to prevent corrosion.

Multiple Reuse Capability: Can be reused for over 50 casting cycles without loss of quality.

Fast Assembly: Locking connections, pins, and wedges—often without the need for bolts and nuts.

Main Components of Modular Formwork

| Component | Application |

|---|---|

| Modular Panel | Main section for holding fresh concrete |

| Soldier | Vertical reinforcement member to withstand concrete pressure |

| Horizontal Brace | Provides lateral stiffness to the formwork |

| Wedge & Pin | Quick and secure connection of formwork parts |

| Concrete Pouring Platform Bracket | Ensures safety and working position for operators |

| Wing Nut & Tie Rod | Tighten formwork from both sides to apply even pressure |

Applications in the Concrete Industry

Casting concrete walls (shear, retaining, architectural)

Forming circular and square columns

Foundation and deep footing formwork

Slabs, bridges, and massive concrete structures

High-rise and mass housing projects

Advantages Over Traditional Formwork

Faster Execution: Pre-fabricated design and simple connections ensure much quicker assembly and dismantling.

Higher Dimensional Accuracy: Precise steel panel edges prevent distortions in finished concrete.

Cost Efficiency for Medium & Large Projects: Over 50–100 reuses per panel vs. 3–5 for wooden formwork.

Environmental Sustainability: Reduces wood and plastic use, supporting green construction practices.

Improved Safety: Compatible with heavy-duty bracing, scaffolding, and safe working platforms.

Comparison of Modular Formwork with Other Formwork Systems

| Feature | Modular Metal Formwork | Wooden Formwork | Plastic Formwork |

|---|---|---|---|

| Service Life | 50–100 uses | 3–5 uses | 10–15 uses |

| Installation Speed | High | Medium | High |

| Initial Cost | Relatively high | Low | Medium |

| Project Lifetime Cost | Very cost-effective | High (frequent replacements) | Medium |

| Moisture Resistance | Very high | Weak | High |

| Dimensional Accuracy | Highly precise | Limited | Limited |

| Suitable for Large Projects | ✔ Yes | ✘ No | ✔ Yes (to some extent) |

Market Status of Modular Formwork in Iran

Growing demand in infrastructure projects:

National civil works such as railways, dams, bridges, and metro systems

Mass housing projects (National Housing Movement)

Oil & gas projects requiring large-scale and precise formwork

Industrial projects including silos, power plants, and refineries

Export opportunities:

Iran, due to its competitive steel prices and skilled workforce, can supply modular formwork to neighboring countries such as Iraq, Afghanistan, Syria, Armenia, and Turkmenistan.

Installation and Implementation Steps in Construction Projects

Site preparation – Ensure the ground or foundation is leveled and ready for formwork placement.

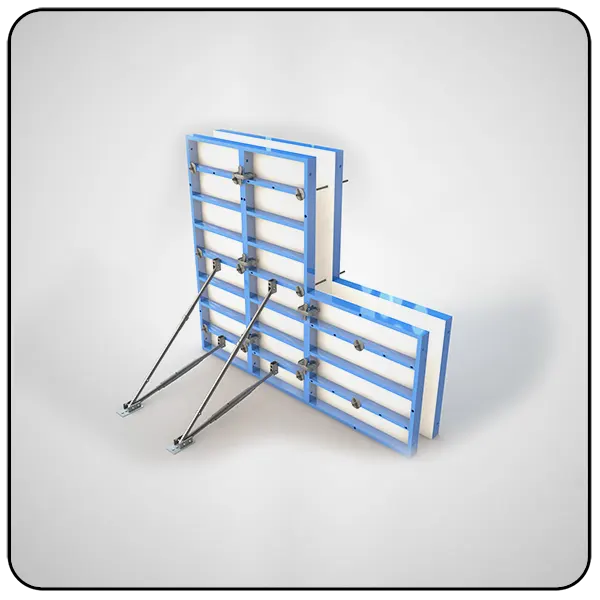

Panel assembly with modular connections – Panels are joined using locking pins and wedges or spring pins; soldiers and horizontal braces are installed for stability.

Level and safety inspection – Check alignment using laser levels or water levels; install pouring platforms and safety rails.

Concrete pouring and vibration – Fresh concrete is placed and compacted using vibrators.

Dismantling after curing – Panels are removed carefully after 24–48 hours without damaging the concrete surface.

International Standards for Modular Formwork

ASTM A36 / DIN 17100 – Standards for structural steel raw materials

ISO 9001:2015 – Quality management system for manufacturing processes

EN 1065 – Standards for vertical support components (props)

ACI 347 – Guidelines for concrete formwork design and construction

Mahyar Sepahan strictly complies with these standards to provide safe and reliable products for both domestic and export projects.

Common Applications of Modular Formwork in Civil Projects

High-rise buildings – Columns, shear walls, elevator shafts, stair cores

Road & bridge projects – Retaining walls, abutments, concrete piers

Industrial & petrochemical facilities – Tanks, utility channels, equipment platforms

Dam construction & hydraulic structures – Piles, curved/radial formwork, arched sections

Power plants & refineries – Heavy foundation pours and large high-pressure slabs

Main Components of Modular Formwork

Flat and corner panels – Made from standard-thickness steel with anti-corrosion coating

Horizontal & vertical soldiers – Transfer loads and increase resistance to concrete pressure

Tie rods and wing nuts – Adjust spacing and prevent deformation

Clamps, pins, and wedges – Ensure quick and secure assembly

Concrete spacers – Maintain correct concrete thickness between form faces

Release agents – Facilitate easy stripping and prevent concrete adhesion

Maintenance Strategies for Extending the Service Life of Modular Formwork

Regular cleaning after each use

Oiling the surface of the formwork to prevent corrosion

Periodic inspection of welds, clamps, and connections

Storage in a dry space, away from moisture and acidic materials

Safe handling using cranes or forklifts for transportation

Key Points for Choosing the Right Modular Formwork

When selecting modular formwork, considering the following factors will help optimize time, cost, and project quality:

Type of project and concreting dimensions

For high-rise projects with high concrete pressure, thicker steel sheets and reinforced connections are required.

In contrast, for lighter or low-rise projects, simpler and more economical formworks are sufficient.Need for special design or customization

If the project includes angles, curves, or unique shapes, the ability to manufacture customized modular formwork in special dimensions becomes crucial.Transportation and assembly constraints

In cases where the project site has limited access, lighter and segmented formworks are recommended for easier transportation and handling.Compatibility with existing scaffolding and support systems

The selected formworks should be compatible with the project’s existing support structures.

Why Modular Formwork Is a Smart Investment

Minimizes human error compared to traditional formwork

Significantly reduces project execution time

Ensures high-quality concrete surfaces without the need for additional plastering

Can be rented or resold after project completion

Saves on manpower through fast and modular installation

Comparison Between Modular and Wooden Formwork

| Feature | Modular Formwork | Wooden Formwork |

|---|---|---|

| Resistance to pressure | High | Low |

| Service life | Over 80 uses | Around 5–8 uses |

| Dimensional accuracy | Precise, industrial | Dependent on worker skill |

| Installation speed | Fast | Time-consuming |

| Reusability | Very high | Limited |

Why Mahyar Sepahan Modular Formwork?

Precision manufacturing with CNC machines

Corrosion-resistant coating (galvanized or epoxy)

Custom design based on project drawings

Technical consultation and on-site supervision during formwork installation

High-capacity mass production for large-scale projects

Product warranty and after-sales service

Packaging, Transportation, and Storage of Modular Formwork

After completing concrete casting, the way formworks are handled greatly affects their lifespan and future performance. Companies like Mahyar Sepahan, by following proper packaging and logistics principles, ensure the quality of formworks in every usage cycle.

Steps for Proper Maintenance:

Wash immediately after use with a water jet or industrial brush

Completely dry to prevent rust

Oil the metal surfaces to increase lifespan

Store in a dry, covered, and insulated place

Stack and label in batches for reuse

Advantages of Modular Formwork in Large Infrastructure Projects

Metro Projects

Use of modular formwork in concrete tunnel walls, stations, and metro track foundations reduces execution time and ensures high precision in curves and angles.

Dam Construction

In dam projects, specially designed curved modular formworks can be used in large sections and under high pressure without deformation.

Water and Sewer Structures

Thanks to high resistance to moisture and pressure, modular formwork is an excellent choice for water channels, tanks, and manholes.

Modular Formwork Market in Iran and Export Opportunities

With the growth of construction projects, especially in the private sector and mass housing, the demand for modular formwork increases every year. Additionally, neighboring countries such as Iraq, Afghanistan, Armenia, and Syria present attractive target markets for exporting Iranian modular formwork.

Mahyar Sepahan manufactures formwork in compliance with global standards and has high export capacity in this sector.

Final Summary: Why Modular Formwork is a Smart Choice

| Criteria | Mahyar Sepahan Modular Formwork |

|---|---|

| Execution Speed | Very High |

| Dimensional Accuracy | Precise and as per design |

| Reuse Cycles | Over 80–100 times |

| Safety | Reliable for high-rise projects |

| Economic Savings | Significant in large projects |

| Technical Support | Provided by a specialized team |

FAQ – Frequently Asked Questions

Is modular formwork suitable for vertical concreting?

Yes, it is suitable for vertical walls, columns, polygonal sections, and even special structures like bridges.

How many times can modular formwork be reused?

With proper maintenance and cleaning, each formwork can be used up to 100 times.

How should formworks be stored after use?

By washing and oiling the surface, then stacking them in steel or wooden pallets.

Final Note – Why Mahyar Sepahan?

If you are looking for quality, durability, support, and real savings in your construction projects, Mahyar Sepahan modular formwork is the smart choice. Our expert team is ready to provide free consultation, custom formwork design, and after-sales service throughout Iran.

📞 Contact us for free consultation and purchase:

Mahyar Sepahan Co.

+98 912 118 0029

mahyarsepahan.com