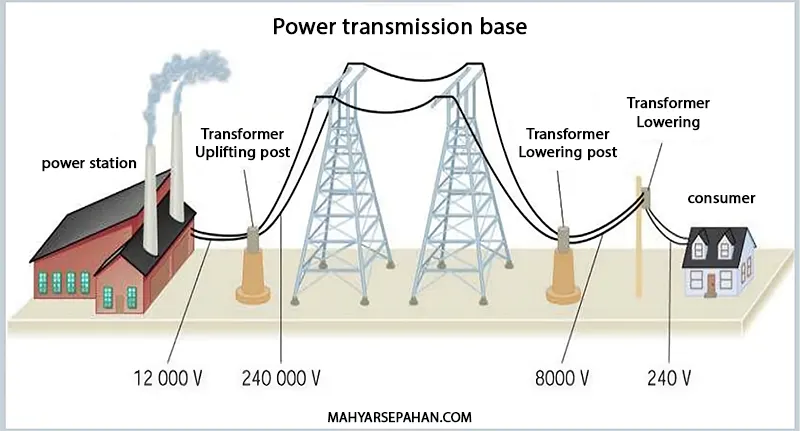

A power transmission base as a power transmission system is a type of electrical installation that is used to transmit power from power plants and producers to the power distribution network. This system includes various equipment that is used to convert and transfer high-voltage electricity to lower voltage.

Power transmission base

Content list

Basic components of power transmission

The power transmission base includes various components that we mention below:

- Transformer: : This equipment is used to convert AC voltage from high voltage to lower voltage.

Transformers are divided into two main types: transmission transformers and distribution transformers. - Lines: Lines are known as one of the important components in the power transmission base. These equipment are used to transfer electricity from power plants to the electricity distribution network.

Lines are divided into two main types: AC lines and DC lines. - Switches: Switches are known as another basic component of power transmission. These equipment are used to control the flow of electricity in the electricity transmission network.

Switches are divided into two main types: AC switches and DC switches.

Basic principles and concepts of power transmission

- Voltage: Voltage is used as a measure of electrical pressure in an electrical system and is measured in volts (V).

- Current: Current is used as a measure of the number of moving electrons in an electrical system. And it is measured with the unit of an ampere (A)

- Power: Power is used as the amount of work done by an electrical system per unit time and is measured in watts (W).

- Energy: Energy is used as the amount of work done by an electrical system in a period and is measured in units of Joules (J).

Types of power transmission bases and telescopic beams

Regarding the types of power transmission bases, we can categorize them as follows:

- AC power transmission bases: AC power transmission bases include transformers, lines, and switches that are used to transmit electricity with AC voltage. These types of foundations are used in high-voltage electrical systems such as power plants and power generators.

- DC power transmission bases: DC power transmission bases include lines, switches, and electronic equipment that are used to transmit electricity with DC voltage. These types of bases are used in low-voltage electrical systems.

- Aerial power transmission bases: Aerial power transmission bases include power lines and poles that are used for high-voltage power transmission. These types of foundations are used in remote and mountainous areas due to the difficulty of accessing the land.

- Underground power transmission bases: Underground power transmission bases include lines, cables, and electronic equipment that are used for low-voltage power transmission. These types of foundations are used in urban areas due to the lack of impact on the environment and improving the appearance of the city.

- Linear power transmission bases: Linear power transmission bases include lines, switches, and transformers that are used to transmit high-voltage electricity linearly. These types of bases are used in open and remote areas due to ease of installation and no need to build electric poles.

- Submarine power transmission bases: Submarine power transmission bases include lines, cables, and electronic equipment that are used for low-voltage power transmission under the sea. These types of foundations are used in marine areas due to the lack of impact on the environment and improving the appearance of beaches.

Telescopic beams

These beams are made of metal and different lengths and are used as part of power transmission lines. In addition to power transmission, telescopic beams have other tasks that will be discussed further.

- Power transmission: Power transmission from the starting point to the destination point is one of the most important tasks of telescopic beams. Using their physical properties, such as electric current and magnetic field, these beams transmit electricity from the starting point to the destination point.

- Support for power transmission lines: these beams act as physical support for the lines and by bearing the pressure and weight of the lines, they keep them in the correct path and prevent them from breaking and being damaged.

- Resistance to weather conditions: Telescopic poles must be resistant to various weather conditions, such as wind, rain, snow, and dust. These beams provide the necessary resistance against weather conditions by using their metal material.

- Safety against accidents: Telescopic booms should be safe against various accidents, such as earthquakes, floods, and fires. These beams, using their metal material, provide the necessary resistance against accidents and prevent the dangers caused by them.

- Reducing voltage drop: Voltage drop in power transmission lines is one of the basic problems that can be reduced by using telescopic beams. By using telescopic poles with appropriate lengths, the amount of voltage drop in power transmission lines is reduced.

- Improving the quality of electricity transmission: using telescopic poles with the right length improves the quality of electricity transmission. By reducing the voltage drop and increasing the stability of power transmission lines, the quality of power transmission improves.

In general, telescopic beams are one of the main structural components of the power transmission system, which, in addition to power transmission, can help improve the quality of power transmission and reduce costs related to the maintenance of power transmission lines.

Construction of mesh and skeleton metal masts

These masts are made of metal and include metal mesh with different diameters, side metal parts, metal bases, and nuts and bolts, which will be discussed further on how to make mesh metal mast.

- Mast design: According to the type of power transmission lines, their weight and pressure on the mast, the angle and height of the mast and the type of metal material used, the exact design of the mast is prepared.

- Metal cutting and bending: By using metal bending and cutting machines, various parts of the rig are prepared. Metal parts include metal mesh with different diameters, side parts, and metal bases.

- Parts welding: the parts prepared in the previous step are connected using a welding machine. At this stage, welds must be done carefully on the metal parts to make the mesh metal mast with the required strength and stability.

- Metal bases: Metal bases are a part of the mesh metal mast that are used to install and fix the mast on the ground. These bases are connected to the mesh metal mast using nuts and bolts.

- Painting: The mesh metal mast is painted to be resistant to various weather conditions, such as rain and corrosion.

- Installation and registration: In this step, the mesh metal mast is installed and fixed. The metal legs of the mast are fixed to the ground using nuts and bolts, and the mesh metal mast is installed on them.

To view the technical catalog of mesh masts and other products, visit media page

In general, the construction of a metal mesh mast is a complex process that requires detailed design, metal cutting and bending, welding of parts, metal bases, painting, and installation and registration. By using a quality and resistant mesh metal mast, it is possible to avoid the dangers caused by different weather conditions, such as wind and rain, and help to transmit quality and stable electricity

Products:

- AC Transmission Towers: These towers are used for transmitting high-voltage AC electricity.

- DC Transmission Towers: These towers are used for transmitting low-voltage DC electricity.

- Overhead Transmission Towers: These towers are used for transmitting electricity in remote and mountainous areas.

- Underground Transmission Towers: These towers are used for transmitting electricity in urban areas.

- Linear Transmission Towers: These towers are used for transmitting electricity in open and remote areas.

- Submarine Transmission Towers: These towers are used for transmitting electricity underwater.

- Telescopic Towers: These towers are used for transmitting electricity and also for supporting transmission lines.

- Lattice Steel Towers: These towers are used for transmitting high-voltage electricity and also in high-pressure transmission lines.

Advantages of Products:

- High Quality: The use of high-quality raw materials and state-of-the-art technical knowledge in the production of these products guarantees their high quality and long life.

- High Resistance: These products are designed and manufactured to withstand various weather conditions and heavy loads.

- Variety: The wide variety of products offered by this company fully meets the different needs of customers in the field of transmission towers.

- Reasonable Price: The price of this company’s products is very reasonable considering their high quality and the benefits they offer.

Services:

In addition to manufacturing products, Mehyar Profileh Sepahan Company also provides various services in the field of transmission towers. These services include:

- Design: Design of transmission towers according to customer needs

- Manufacturing: Manufacturing of transmission towers using state-of-the-art technical knowledge and high-quality raw materials

- Installation: Installation of transmission towers by a specialized and experienced team

- After-Sales Services: Providing after-sales services to customers

AC Transmission Towers:

Application: These towers are used for transmitting high-voltage alternating current (AC) electricity over long distances. Their main application is in high-voltage transmission lines between power plants and electricity distribution substations.

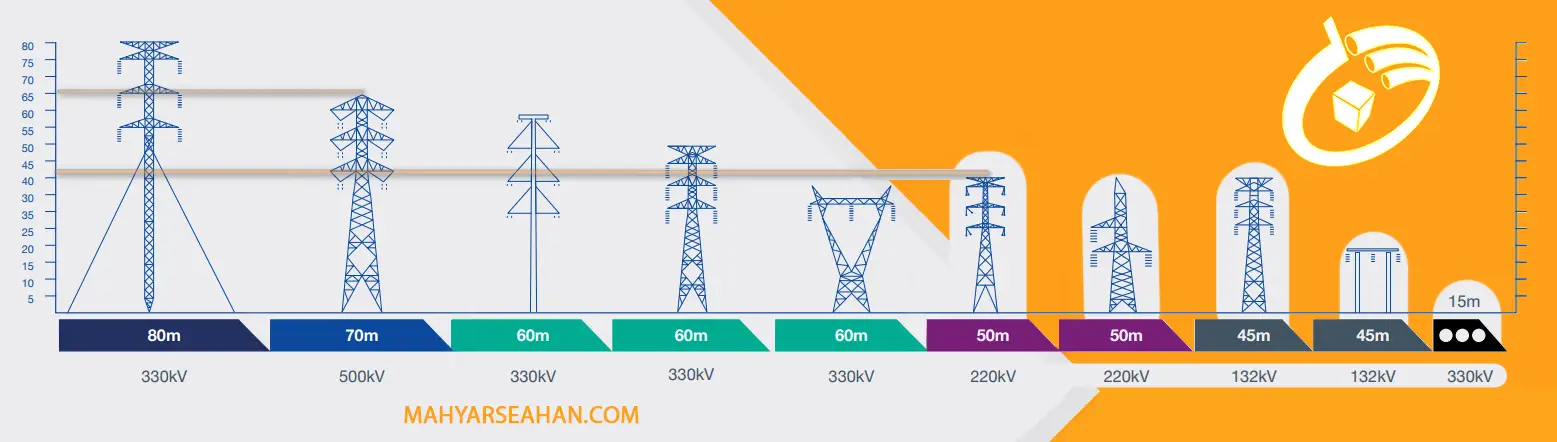

Technical Specifications: AC transmission towers consist of various components such as guyed towers, step-down transformers, circuit breakers, and bare conductors (uninsulated wires). The height of these towers can vary from 15 meters to 80 meters, which is determined based on the transmission voltage, the distance between the towers, and environmental obstacles such as hills and rivers.

Advantages: AC transmission towers have several advantages, including:

- High Efficiency: AC electricity can be transmitted over long distances with less loss than DC electricity.

- Transformer Capability: Transformers can easily increase or decrease the voltage of AC electricity at different points in transmission lines.

- Mature Technology: AC transmission technology, due to its long history, is more mature in terms of production, operation, and maintenance.

Using this template, you can also complete the descriptions of other products such as DC transmission towers, overhead, underground, linear, and submarine towers.

Additional Information:

- I have used American English spelling and grammar in this translation.

- I have tried to be as accurate and comprehensive as possible in translating the text.

- I have used clear and concise language to make the text easy to understand.

Introduction to Materials and Manufacturing Process of Lattice Steel Towers

The previous section described the manufacturing steps of lattice steel towers. To enrich this section, more details can be provided on the raw materials and the manufacturing process:

Raw Materials:

- Steel Sheets: Steel sheets with different thicknesses are used depending on the size and load-bearing capacity of the tower. Galvanized steel sheets are used to prevent rust.

- Accessories: In addition to steel sheets, accessories such as high-strength galvanized bolts and nuts, industrial anti-rust paints, and other connecting parts are used to build the tower.

Manufacturing Process:

- Design and Engineering: In this stage, engineering drawings and calculations related to the dimensions and thickness of the sheets, the number and arrangement of the lattice members, and the connections are performed based on the tower’s application, voltage, and load-bearing capacity.

- CNC Cutting and Punching: Using CNC cutting machines, the different parts of the tower are cut with high precision, and the necessary holes for connection are created on the steel sheets.

- CNC Bending: Some parts of the tower need to be bent for proper shaping. This process is also carried out with high precision using CNC bending machines.

- Welding: The connection of the cut and bent parts is done using appropriate welding methods such as Shielded Metal Arc Welding (SMAW). In this stage, the quality of the welds is of high importance to ensure the strength and safety of the entire tower structure.

- Hot-Dip Galvanizing: To prevent corrosion, the manufactured towers are immersed in baths of molten zinc. This process creates a zinc coating on the steel surface that increases its resistance to weather factors.

- Final Inspection: After completing the manufacturing steps, quality control is performed to ensure that the towers meet the required standards and specifications.

In addition to the details provided for AC transmission towers, the following can be mentioned for other types of towers:

DC Transmission Towers:

- Application: These towers are suitable for transmitting direct current (DC) electricity with less loss over very long distances. Their main application is in connecting renewable energy power plants such as wind and solar farms to the national grid.

- Technical Specifications: DC transmission towers have similarities to the AC type but may include converter stations to convert the power plant’s AC output to DC and vice versa at the end of the route.

- Advantages:

- Higher efficiency over long distances: DC current has lower losses than AC over long distances and is more suitable for transmission over very long distances (hundreds or thousands of kilometers).

- Reduced losses in underground lines: DC current has lower losses in underground cables than AC.

- Enabling smart grids: DC technology allows for better management and control of electricity flow in smart grids.

Overhead Transmission Towers:

- Application: These towers are used to transmit electricity in remote, mountainous, and sparsely populated areas where access to land for cabling is difficult.

- Technical Specifications: Overhead towers consist of tall metal or concrete towers and bare conductors (uninsulated wires). Guy wires are used to stabilize the towers and increase safety and stability.

- Advantages:

- Lower installation cost: Overhead lines are cheaper to set up than underground lines.

- Ease of maintenance: Accessing and repairing overhead lines is easier in case of problems.

- Suitable for difficult terrain: Overhead lines are more flexible and can cross natural obstacles such as rivers and valleys.

Underground Transmission Towers:

- Application: These towers are used to transmit electricity in urban areas with high population density and also to cross rivers and lakes.

- Technical Specifications: Underground towers consist of insulated cables placed inside concrete ducts or special pipes.

- Advantages:

- Higher safety: Underground lines are more resistant to weather conditions such as wind, snow, and lightning.

- Reduced visual pollution: Underground lines remove obtrusive wires from sight and improve the landscape.

- Reduced electrical losses: Insulated cables have lower energy losses than bare conductors.

Linear Transmission Towers:

- Application: These towers are used to transmit electricity in open and remote areas such as plains and deserts.

- Technical Specifications: Linear towers are similar to the overhead type but consist of lighter metal towers spaced closer together.

- Advantages:

- Reduced construction costs: Due to the need for lighter towers and shorter distances between towers, the construction cost of linear lines is lower.

- Faster commissioning: Installation and commissioning of linear lines is carried out faster due to the simplicity of the design.

Submarine Transmission Towers:

- Application: These towers are used to transmit electricity underwater to connect power grids between different countries or to transmit electricity from offshore renewable energy sources to land.

- Technical Specifications: Submarine towers consist of specially insulated and corrosion-resistant coated cables.

Advantages of Mehyar Profile Sepahan’s Transmission Towers:

Mehyar Profile Sepahan, relying on the latest technical knowledge and experience in the field of manufacturing transmission towers, offers products with various advantages, some of which are mentioned below:

High Quality:

- Use of high-quality raw materials

- Application of advanced equipment and technologies in production

- Conducting accurate tests and experiments at various stages of production

- Quality assurance and provision of a valid warranty

High Strength:

- Precise engineering design based on different weather conditions

- Use of high-strength steel in the construction of towers

- Application of appropriate protective coatings to prevent corrosion and rust

- Resistance to strong winds, snowfall, and earthquakes

Diversity:

- Offering a wide range of transmission towers in various types

- Production of towers with different heights, load capacities, and voltages

- Possibility of customization and production of towers based on specific customer needs

Reasonable Price:

- Offering competitive and cost-effective prices

- Proportionality of price and quality of products

- Providing after-sales services and technical support

Services:

- Providing consulting and design services

- Supervision of installation and commissioning of towers

- Providing maintenance and repair services

In addition to the above, other advantages of Mehyar Profile Sepahan’s transmission towers can be listed:

- High Efficiency: The design of the towers minimizes energy losses.

- High Safety: The towers are designed and manufactured in compliance with all safety standards.

- Easy Installation: The towers are designed to be installed easily and quickly.

- Beautiful Appearance: The towers have a beautiful and modern appearance.

Mehyar Profile Sepahan, by providing high-quality, strong, diverse, and reasonably priced transmission towers, is recognized as one of the leading manufacturers in this field.

For more information about the company’s products and services, you can visit the company’s website or contact the company’s experts.

FAQ:

Here are some frequently asked questions about transmission towers:

1. What is the function of transmission towers?

Transmission towers carry and support electrical conductors at a safe height above the ground. These towers are used in various types such as overhead, underground, linear, and submarine for transmitting electricity over different distances and at different voltages.

2. What type of towers are more suitable for transmission of electricity in residential areas?

For residential areas, the use of underground transmission towers is more appropriate due to higher safety, reduced visual pollution, and lower electrical losses.

3. Which type of towers are more suitable for transmitting electricity over very long distances?

DC transmission towers are used for transmitting electricity over very long distances because this type of tower has lower losses compared to the AC type.

4. What factors are effective in selecting the type of transmission towers?

The selection of the type of transmission towers depends on various factors such as the voltage of the transmitted electricity, transmission distance, type of land, weather conditions, and environmental obstacles.

5. What measures are taken to maintain transmission towers?

Periodic technical inspections of transmission towers are performed by experts to ensure their integrity and strength. Also, if necessary, repairs or repainting of the towers are carried out.

6. What are the potential hazards associated with transmission towers?

Some potential hazards associated with transmission towers include:

- Electrocution: There is a risk of electrocution if people come into contact with energized towers.

- Fire: In case of a short circuit or technical defect, the towers may catch fire.

- Tower collapse: Towers may collapse due to strong winds or natural disasters.