The lighting towers must be made of hot galvanized iron inside and outside and have circular or polygonal sections and be higher than the ground level and be designed to carry several (4-12) floodlights as needed.

The lighting towers must be made of hot galvanized iron inside and outside and have circular or polygonal sections and be higher than the ground level and be designed to carry several (4-12) floodlights as needed.

These towers are designed and built in such a way that they are suitable for use in lighting highways and public squares.

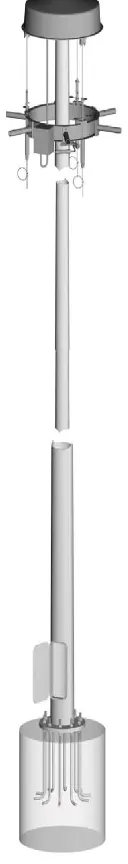

Optical towers consist of several joints, the first lower link is not less than 10 meters, the joints are assembled in place by inserting the end of the lower link into the beginning of the upper link with pressure or by using sliding joints, welding in place is not allowed. At the bottom of the tower, there is a fixed base of galvanized iron which is made of chips to bear the full pressure of the tower base. Also, the base has reinforcing blades.

Between the nail holes of the tower, a door with suitable dimensions to reach the internal distribution board, which includes the main sector, as well as a box for the electric lift and the distribution board, is installed and built. The tower is made of iron or suitable and standard alloy materials that are not affected by atmospheric factors, and its door is fixed with invisible hinges and has a strong lock with proper strength of the door.

A galvanized iron nail is welded inside the ground next to the door opening and a metal ring and nut of the same type is intended for connecting the earth wire.

In the case of lanterns or floodlights, it is made of hot-dip galvanized iron corners and can accommodate the required number of lanterns and fixed supports and consists of two parts connected by screws. that are easily separated from the tower. The holder is designed in such a way that it allows the distribution of light in each recess and also has a roller. This holder is made of moisture-resistant metal to maintain its balance during ascent and descent. This carrier has a box for electrical equipment that is resistant to it. Weather conditions are equipped with a suitable connection base for the end, connecting rod, and grounding nail, as well as having a power socket for the possibility of testing the lanterns when the carrier is at the bottom of the tower, and connecting cables between the terminal box. The floor of the tower. And the connection box on the base is a flexible type that includes several insulated connectors with high thermal resistance and is in specific colors. Necessary precautions to separate the electric cables from the metal ropes before passing over the pulleys. The designated routes for the cables include several obstacles for the movement of the pulleys during operation, and this can be done by using rods for the cables. It did during lifting and lowering.

Lighting towers with a height of 12 to 60 meters are produced in 3 types: fixed, manually movable, and movable with an electric motor. The outer surface of these towers is hot galvanized and the parts are mounted overlapping and the safety of the towers is secured by a lock.

Constituent parts

Content list

basket (head or crown)

The most important parts of light towers and lighting bases are located in the upper part of the structure, the basket part (head or crown) on which the Led projector is installed, and the mechanical or electronic part at the bottom of the tower. These two important parts cause the head of the tower to move vertically up and down. Other parts include a multi-faceted trunk (mast-mast base or side), base plate, lightning rod, rain cap, steel wire and cable, electrical panel, manual hoist (equipped with a winch and manual handle) or an electric one equipped with an electronic gearbox motor , bolt and nut, corps, Led projector, and alarm light.

Base plate and Lachki

One of the most important and sensitive parts of the lighting tower is the base plate. This section is actually the point where the light tower is erected. The base plate is supposed to withstand the entire weight of the base during wind and storms, and for this reason, the necessary safety points must be taken into account when installing the lighting base. In this section, if the accuracy is not sufficient and the size or thickness of the tower is not correct, or if there is a weakness during welding, the possibility of the lighting tower falling due to earthquake, wind, etc. is very high and it can cause many unfortunate incidents. In most cases, the dimensions of the base plate are calculated according to the lower opening of the lighting tower, so the smaller the opening of the tower, the smaller the radius of the base plate and vice versa.

Lakhki is also designed in the same way. Lachi is the triangular section that is welded from one side to the base plate section and from the other side to the body of the lighting tower. In fact, its use is to strengthen the connection of the tower body to the base plate and increase the tolerance of the lighting tower against pressure and stress. Make sure that the thickness of the elastic should be proportional to the thickness of the base plate

Electrical panel

It is a compartment in which electrical equipment is placed. One of the reasons for using the switchboard is to raise the safety level when, for example, there is a short circuit in the equipment. Also, collecting all electric parts in this box for ease of use by the operator is another important reason. With a simple explanation about the electrical panel, we must say that it does exactly the same thing as the electricity meter used in homes. The switchboard includes parts such as a contactor, switch, bimetal, relay, measuring equipment, current transformer, conductor, and body parts.

Electric motor – electromotor

The electric motor converts electronic energy into mechanical energy. It is available in the market in AC and DC models, with and without brushes, and multi-phase (single-phase, two-phase, and three-phase). It is necessary to use an electric motor in towers with a height of more than 12 meters and a basket equipped with a sodium vapor projector with several more than 8. The weight of sodium vapor projectors is higher than Led and makes the basket heavy. The gearbox electric motor is built inside the structure, and for this reason, the diameter of the lower opening of the structure is considered larger during the design. The reason for the higher price of the motorized tower, in addition to the addition of the motor to the structure, is the change in the diameter of the lower opening.

tow wire

There are many varieties of wire ropes in the construction of optical masts and lighting bases, and the environmental conditions are the reason for choosing this variety. Anti-rust and anti-moisture coatings with galvanized coating, and steel coatings with high resistance to rust and heat are among them. Uncoated samples are suitable for use in dry and rust-free climates, while jacketed and protective samples are suitable for wet areas, so when ordering the product, be sure to consider your canvas and area.

Lightning rod, lightning rod – rod lightning rod

The work of a lightning arrester or lightning arrester is clearly defined. When lightning strikes the ground, it penetrates any conductive material or object to find a way to the ground and discharge. In some cases, it can completely destroy the device struck by lightning, or lead to a fire. For this reason, we use lightning rods to prevent this from happening. In fact, the lightning rod is a protective system against the flow of electricity and protects the structure from sudden lightning strikes. Since masts and towers are conductive, they can easily absorb lightning. For this reason, and in many places, to increase safety and prevent breakdowns, lightning rods are used. Because if it is not used, it can cause a fire due to a lightning strike and cause various problems in addition to power outages. As a result, the electricity in the area will fail.

What foundation is suitable for installing a light tower?

The type of foundation suitable for installing a light tower depends on the height and weight of the tower and the soil and ground conditions of the installation site.

If the soil of the installation site of the light tower is sandy: the foundation of steel or concrete foundations is suitable.

If the soil where the light tower is installed has a layer of limestone: steel or concrete foundations with heavy foundations are suitable.

One of the most important tasks of the foundation is to transfer the pressure and weight of the structure to the ground. Usually, 2 foundation samples are used to install the lighting tower. The ready sample is made in the workshop and the sample is concreted at the installation site. The depth and dimensions of the foundation depend on the type of ground (loose or normal) of the installation site. In the first step, the foundation starts with reinforcement, and in the second step, it is time to install bolts. The number of bolts can be selected according to the weight of the structure. Usually, for this in the ready foundation, a template is needed to accurately place the holes on the base plate. In the next step, it is the turn of piping inside the foundation to pass the cables. In the last step, the molding is done and then the foundation construction steps are finished with concreting.

The ready-made foundation is mostly used for light towers and light base examples that have a lower height or are likely to move. To install higher samples, hole digging, reinforcement, and concreting will be started based on the design and plan.

Installing a light tower

For construction and installation, some things must be carefully checked before production. Wind speed, the structure of the ground and the type of soil at the installation site, the weight of the tower, the diameter of the base and the height of the tower, the strength of the light tower mast against natural events such as storms and earthquakes, compliance with international standards and the exact calculation of the foundation and how to implement it, are examples of these things. are. As mentioned in the specification section, the body parts should be assembled on top of each other. This overlapping of the trunks on each other greatly increases the strength of the parts and the overall endurance of the structure. The thickness of the sheet in the lower parts of the structure has a larger diameter, and as we go to the top of the tower, its diameter decreases.

Trunks are made of 6-8-10-12-16 faces and their amount changes from bottom to top. Another point that is important in installing the tower is choosing the number of projectors. Usually, between 4 and 30 projectors can be installed depending on the type of tower. Then the switchboard, which includes all control parts and protection circuits, is installed in a separate compartment next to the tower. The lightning rod (anti-lightning) and the flashing alarm light (danger) are installed in the upper part of the structure for better visibility and also to prevent the collision of flying objects near high towers. In the end, a rain cap is added to the upper part of the tower basket to prevent water droplets from penetrating inside the structure.

Lighting towers (towers and columns) are used to illuminate large areas such as gardens, resorts, squares, streets, bridges, and courtyards of buildings such as hospitals, factories, etc.

When designing and building lighting towers, the following factors should be considered:

• Wind speed and force caused by wind pressure in the area

• Land structure and soil type

• Tower weight to calculate foundations

• Resistance to earthquakes and other natural disasters

• Compliance with international standards