The word modular itself can mean scale and size, meaning that the templates can also be made depending on the structure to be built. The modular molding system is very economical because of its use in the execution of all concrete structures such as wall foundations, columns, beams and slabs.

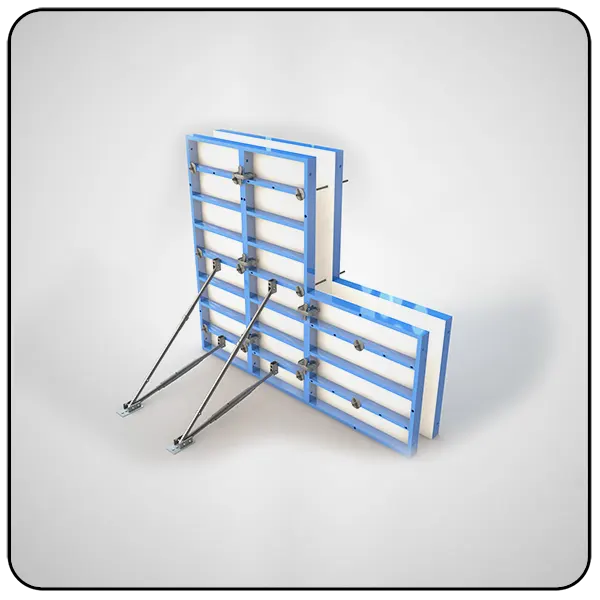

Modular formwork enables custom layouts in concrete bodies and is one of the most essential workshop equipment, with the ability to vary and harmonize with the specific requirements of each project.

Concrete metal molds can be used repeatedly, and the useful life of modular concrete molds depends on the maintenance of the concrete metal molds, at least up to 60 times without deformation and distortion if the concrete is not tossed and dropped.

When executing structures using a metal mold you can achieve a solid, secure, and beautiful structure. Implementation of all foundations, including single, strip,

radius and etc is very simple, economical and fast using modular formats. Composition and joining of metal panels, bracket pipes, fittings such as pins and wedges, molded pipe clamps, punched corners and the use of inner corners, outer corners, and fillers can be molded and executed. At the same time, it should be noted that the foundation is the largest and heaviest part of the concrete structure, and the high volume of concrete and mold filling speed results in the lateral pressure of the concrete and its shear force.

Mehyar Profile Sepahan Modular Formwork: A Flexible and Cost-Effective Solution for Construction

Content list

Mehyar Profile Sepahan modular formwork has revolutionized the concrete construction industry. These formworks, which are made up of metal panels of different sizes, offer a flexible and cost-effective solution for a wide range of projects.

Advantages of using Mehyar Profile Sepahan modular formwork:

- Adjustability: Modular formwork can be easily adjusted to different sizes and shapes to suit the needs of each project. This allows contractors to reuse the formwork on multiple projects and minimize their costs.

- Speed and ease of use: Modular formwork is designed to be easy to assemble and disassemble. This allows contractors to complete projects faster and with greater efficiency.

- High quality: Mehyar Profile Sepahan modular formwork is made of high-quality steel and is resistant to impact and abrasion. This ensures that concrete structures built with these formworks are of high quality.

- Safety: Mehyar Profile Sepahan modular formwork is designed to be highly safe. This allows contractors to complete their projects with peace of mind.

Applications of Mehyar Profile Sepahan modular formwork:

- Foundations: Modular formwork can be used to formwork all types of foundations, including individual, strip, and raft foundations.

- Walls: Modular formwork can be used to form concrete walls of different thicknesses.

- Columns: Modular formwork can be used to form concrete columns of different sections.

- Slabs: Modular formwork can be used to form concrete slabs of different thicknesses.

Mehyar Profile Sepahan:

Mehyar Profile Sepahan is a leading manufacturer of modular formwork in Iran. With a proven track record in the production and supply of modular formwork, the company is recognized as one of the most trusted brands in the industry. Mehyar Profile Sepahan offers a wide range of modular formwork and support services to help contractors complete their projects successfully.

Differences between Mehyar Profile Sepahan modular formwork and other formwork:

Mehyar Profile Sepahan modular formwork offers several advantages over other formwork available in the market, some of which include:

- Adjustability:

Mehyar Profile Sepahan modular formwork is available in various dimensions and sizes and can be easily connected to each other vertically and horizontally. This feature provides high flexibility for contractors to use these formworks in various projects with complex and diverse geometries.

In contrast, many traditional formworks, such as wooden or metal formworks, are produced in fixed dimensions and have limited adjustability. This can challenge contractors in executing projects with specific geometries.

- Speed of execution:

The easy and quick connection system of Mehyar Profile Sepahan modular formwork allows contractors to perform formwork operations in a shorter time compared to traditional formwork.

The use of hydraulic and pneumatic jacks alongside these formworks significantly increases their installation and disassembly speed.

In contrast, traditional formworks require more time for installation and disassembly due to their more complex connections and the need for special tools.

- High quality:

Mehyar Profile Sepahan modular formwork is produced using high-quality steel sheets and state-of-the-art welding and laser cutting technologies. This provides high strength and durability to the formworks and prevents their deformation or damage during use.

The smooth and polished surface of the formworks results in high-quality and flawless concrete.

In contrast, traditional formworks, due to the use of low-quality raw materials and weak connections, may bend or break under the pressure of concrete and affect the final quality of concrete.

- Safety:

The design and structure of Mehyar Profile Sepahan modular formwork are based on safety principles.

Smooth and burr-free edges, non-slip and anti-slip surfaces, and secure connections are among the features of these formworks.

Mehyar Profile Sepahan Modular Formwork:

- Adjustability: Various dimensions and sizes, connectability, high flexibility for use in various projects.

- Speed of execution: Easy and quick connection system, use of hydraulic and pneumatic jacks, reduced installation and disassembly time.

- High quality: High-quality steel sheets, welding and laser cutting, high strength and durability, high-quality concrete.

- Safety: Safe design and structure, smooth edges, non-slip and anti-slip surfaces, secure connections, reduced risk of accidents.

- Cost-effectiveness: Long service life, reusability up to 60 times, reduced قالب purchase costs.

- Reduced concrete waste: Very few joints, economical savings, environmental protection.

- High-quality concrete finish: Smooth and polished surfaces of the formwork, concrete with a smooth and uniform appearance.

- After-sales service: Technical consulting, installation and disassembly training, spare parts supply.

Traditional Formwork Methods:

- Limited adjustability: Fixed dimensions, lack of flexibility in executing projects with specific geometries.

- Low speed of execution: More complex connections, need for special tools, longer installation and disassembly time.

- Low quality: Use of low-quality raw materials, weak connections, possibility of bending or breaking of formwork, low quality of concrete.

- Low safety: Sharp edges, uneven surfaces, unsafe connections, higher risk of accidents.

- High cost: Short service life, need to replace and purchase new formwork, increased costs.

- High concrete waste: Many joints, concrete waste, environmental damage.

- Unsatisfactory concrete finish: Uneven surfaces of the formwork, concrete with an incomplete and uneven appearance.

- Limited after-sales service: No support and training services provided.

Comparison Table of Mehyar Profile Sepahan Modular Formwork with Traditional Formwork Methods:

| Feature | Mehyar Profile Sepahan Modular Formwork | Traditional Formwork Methods |

|---|---|---|

| Adjustability | Various dimensions and sizes, connectability, high flexibility for use in various projects | Fixed dimensions, lack of flexibility in executing projects with specific geometries |

| Speed of execution | Easy and quick connection system, use of hydraulic and pneumatic jacks, reduced installation and disassembly time | More complex connections, need for special tools, longer installation and disassembly time |

| Quality | High-quality steel sheets, welding and laser cutting, high strength and durability, high-quality concrete | Use of low-quality raw materials, weak connections, possibility of bending or breaking of formwork, low quality of concrete |

| Safety | Safe design and structure, smooth edges, non-slip and anti-slip surfaces, secure connections, reduced risk of accidents | Sharp edges, uneven surfaces, unsafe connections, higher risk of accidents |

| Cost-effectiveness | Long service life, reusability up to 60 times, reduced قالب purchase costs | Short service life, need to replace and purchase new formwork, increased costs |

| Reduced concrete waste | Very few joints, economical savings, environmental protection | Many joints, concrete waste, environmental damage |

| Concrete finish | Smooth and polished surfaces of the formwork, concrete with a smooth and uniform appearance | Uneven surfaces of the formwork, concrete with an incomplete and uneven appearance |

| After-sales service | Technical consulting, installation and disassembly training, spare parts supply | No support and training services provided |

As you can see, Mehyar Profile Sepahan modular formwork offers significant advantages in terms of flexibility, speed of execution, quality, safety, and cost-effectiveness compared to traditional formwork methods.

Ordering and Purchasing Mehyar Profile Sepahan Modular Formwork:

Choosing the right formwork for each project is of great importance. Mehyar Profile Sepahan Company, with the help of its experienced team of engineers, is ready to provide free technical consultation to choose the type and volume of modular formwork required for your project. To facilitate the ordering process, the company has considered various methods:

Phone call: By contacting the sales department of Mehyar Profile Sepahan Company, the experienced experts of this department will receive the initial information of your project and provide consultation and estimate the volume and type of required formwork.

In-person visit: If you are willing to visit the products and receive an in-person consultation, you can refer to the head office or sales representatives of Mehyar Profile Sepahan Company.

Online order: The website of Mehyar Profile Sepahan Company provides the possibility of establishing online communication with the sales department. Through this section, you can ask your questions and place an online order.

Quality and price guarantee:

Mehyar Profile Sepahan, confident in the high quality of its products, offers all modular formwork with a written warranty. The company also, relying on domestic production and eliminating intermediaries, always strives to provide its products to customers at the most reasonable price.

Research and development:

Mehyar Profile Sepahan Company, with an experienced team of engineers and designers, is constantly researching and developing to improve the quality and efficiency of its modular formwork.

The company, using the latest technologies and design software, seeks to provide innovative solutions for the needs of the construction industry.

Auxiliary services:

Mehyar Profile Sepahan Company, in addition to providing modular formwork, also offers other auxiliary services such as technical consulting, training on installation and disassembly of formwork, and supplying spare parts to its customers.

These services are provided to facilitate the use of formwork and increase customer satisfaction.

Social responsibility:

Mehyar Profile Sepahan Company, as a responsible company, operates in various fields such as environmental protection, education, and employment.

The company, committed to its social responsibilities, seeks to play a positive role in society and improve the quality of people’s lives.

The future of the formwork industry:

It is predicted that the use of modular formwork in the construction industry will increase in the future due to its many advantages.

Mehyar Profile Sepahan Company, relying on its brilliant history and expertise, strives to be a pioneer in this path and have a significant share in this growing market.

Conclusion:

Mehyar Profile Sepahan modular formwork, with its many advantages such as flexibility, speed of execution, high durability, worker safety, and final concrete quality, is considered one of the top choices for contractors in the construction industry. Comprehensive after-sales services, free consultation, ease of ordering, and reasonable prices are other strengths of this company.

For more information and free consultation, please contact the experienced experts of Mehyar Profile Sepahan Company.

Frequently Asked Questions about Mehyar Profile Sepahan Modular Formwork:

1. What are the applications of Mehyar Profile Sepahan modular formwork?

- Foundation formwork (isolated, strip, raft, etc.)

- Wall formwork

- Column formwork

- Slab formwork

2. What are the advantages of using Mehyar Profile Sepahan modular formwork?

- High adjustability and flexibility

- Speed of execution and ease of installation and disassembly

- High quality and long service life

- High safety and reduced risk of accidents

- Cost-effectiveness and reduced costs

- Reduced concrete waste and environmental protection

- High-quality and smooth concrete finish

3. How much do Mehyar Profile Sepahan modular formwork cost?

The price of the formwork depends on various factors such as the type and dimensions of the formwork, the number required, and the purchase conditions. For accurate pricing information, you can contact the sales experts of Mehyar Profile Sepahan Company.

4. How can I order Mehyar Profile Sepahan modular formwork?

You can order these formwork by phone call, in-person visit, or online order.

5. What does Mehyar Profile Sepahan Company’s after-sales service include?

- Free technical consultation

- Training on installation and disassembly of formwork

- Spare parts supply

6. What should I do to get more information and specialized consultation?

You can contact the experienced experts of Mehyar Profile Sepahan Company via phone call, website, or social media.

7. Is it possible to visit the products and factory of Mehyar Profile Sepahan Company in person?

Yes, it is possible for customers to visit the products and factory in person.

8. What is the warranty and guarantee for Mehyar Profile Sepahan Company’s products?

All Mehyar Profile Sepahan Company products have a warranty and quality guarantee.

9. Is Mehyar Profile Sepahan Company also active in the field of education and holding specialized courses?

Yes, this company is also active in holding specialized training courses for contractors and workers in the construction industry.

10. What information is needed to order modular formwork?

- Project type

- Required dimensions and sizes

- Number of formwork

- Delivery time