Mahyar Sepahan company produces all kinds of tubular Iraqi beams and bases or mesh Iraqi electrical beams:

Tubular Iraqi base or mesh Iraqi pole (Utility pole):

Iraqi base or Iraqi electric pole (Utility pole) is one of the metal structures for electricity transmission, which is produced for the purpose of electricity transmission in Iraq and according to the standards of the Iraqi Ministry of Electricity.

Iraqi transmission towers usually include the following two models:

Iraqi tubular street pole

Content list

Pipe supports or poles, which are also called power poles or telescopic poles, are tubular poles for power transmission or other uses. At the highest point of the base (the crown of the base), a piece of steel is welded in the shape of the Persian number eight, which is also connected by a horizontal interface. Above the bending point and in the middle of the intermediate arm, there is a hole where the cable holder is connected. There are 5 holes in the upper part of the base for this purpose. Depending on the height of the product, it goes below the ground level between 1.5 and 2.5 meters after installation, or sinks into the ground.

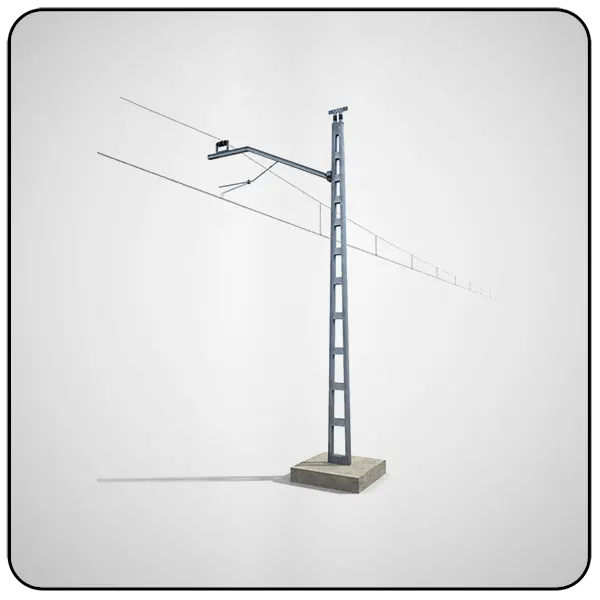

Iraqi lattice street pole

Grid bases, as their name suggests, are a connection of two bases connected to each other, which looks like an equilateral triangle with a very small base and large sides. The material of the body and arms used in the mesh base is made of steel according to the table in the picture and the relevant brochure. This product is manufactured and supplied in galvanized form.

Galvanized metal structures that are used in the neighboring country of Iraq, such as lighting lamp bases or galvanized electricity transmission poles, have similarities with similar Iranian products, but they are basically different in terms of material.

That is, ST37 steel is used in the production of Iranian foundations, while ST51 or ST52 steel is used in the production of tubular Iraqi foundations or in the production of Iraqi grid electricity poles.

Iraqi round and mesh foundations are produced at heights of 9 and 11 meters and after installation, some of the foundation is sunk into the ground.

14 meter mesh base beams

It is the same as the previous product, but it is produced and supplied in 14 meters length. High strength and success in all technical tests are prominent characteristics of this product.

Advantages of Iraqi towers:

- High strength: Iraqi towers are made of high-quality steel and have high strength. This high strength makes the towers resistant to strong winds, snow loads, and other environmental factors.

- Long service life: Iraqi towers have a long service life due to galvanization, and are resistant to rust and corrosion.

- Easy installation: Iraqi towers are easy to install and do not require any special skills or equipment.

- Variety in height: Iraqi towers are produced in different heights and can be used in various applications.

- Reasonable price: Iraqi towers are reasonably priced considering their advantages.

- Recyclability: Iraqi towers are recyclable at the end of their useful life.

- Corrosion resistance: Iraqi towers are resistant to rust and corrosion due to hot-dip galvanization.

Points to consider when choosing an Iraqi tower:

- Height: The height of the Iraqi tower should be selected according to its application.

- Type of load: The type of load that the Iraqi tower must withstand should be considered.

- Environmental conditions: Environmental conditions such as wind and snow load should be considered.

- Price: The price of Iraqi towers varies depending on the height, type of load, and environmental conditions.

More details about Iraqi towers:

Technical specifications:

- Material: ST51 or ST52 steel

- Tensile strength: 4500 to 5200 kg/cm2

- Yield strength: 3200 to 3800 kg/cm2

- Sheet thickness: 3 to 6 mm

- Pipe diameter: 114 to 168 mm

- Height: 9 to 14 meters

- Weight: 200 to 1000 kg

- Coating type: Hot-dip galvanized

Standards:

- Iranian national standard: ISIRI 3364

- Iraqi Ministry of Electricity standard: TSC 1101

Production stages:

- Sheet cutting: Steel sheets are cut to the required thickness and dimensions.

- Bending: The cut sheets are bent into the shape of tubes or lattice sections.

- Welding: The bent parts are welded together.

- Hot-dip galvanizing: The bases are immersed in a hot-dip galvanizing bath to increase their corrosion resistance.

- Quality control: The bases are checked for quality and compliance with standards before loading and shipping.

Applications of Iraqi towers:

- Power transmission: Iraqi towers are widely used in distribution and super-distribution networks in Iraq for power transmission.

- Street lighting: Iraqi towers can be used to light streets, roads, highways and large areas.

- Telephone and telecommunications: Iraqi towers can be used to install telecommunications and telephone equipment, such as BTS towers and telecommunications antennas.

- CCTV cameras: Iraqi towers can be used to install CCTV cameras in streets, roads and public places.

- Billboards: Iraqi towers can be used to install billboards in streets and roads.

- Other applications: Iraqi towers are used in various other applications such as installing signs and warnings, installing traffic equipment, and

Types of connections for Iraqi towers:

Iraqi towers use various connections to connect to cables, lights, and other equipment. Some of the common types of these connections are:

- Brackets: Brackets are metal pieces that are welded to the body of the tower and allow the connection of various equipment. Brackets are available in various shapes and sizes.

- Clamps: Clamps are pieces used to secure cables to the body of the tower. Clamps are available in various types and are selected according to the diameter and type of cable.

- Caps: Caps are plastic or metal pieces that are installed on the top of the tower and prevent water, dust, and other contaminants from entering the tower.

Safety notes when installing Iraqi towers:

- Installation of Iraqi towers should be carried out by experienced and qualified personnel.

- Appropriate safety equipment such as helmets, gloves, and safety shoes must be worn during installation.

- Before installation, the strength of the ground and its ability to withstand the weight of the tower must be ensured.

- A crane or other suitable equipment must be used when lifting and transporting the tower.

- Relevant safety standards must be followed when installing cables and other equipment on the tower.

Mhiyar Sepahan Company:

Mhiyar Sepahan Company is a manufacturer of high-quality Iraqi towers that comply with international standards.

Using modern machinery and equipment, as well as experienced personnel, the company is capable of producing Iraqi towers in various dimensions and sizes, with the required connections.

Mhiyar Sepahan Company provides free consultation services to its customers on the selection and installation of Iraqi towers.

Conclusion:

An Iraqi tower is a strong and high-quality metal structure that has many applications in power transmission, street lighting, telecommunications, and other areas. These towers have attracted the attention of many contracting companies and construction projects due to their high strength, corrosion resistance, long life, easy installation, and reasonable price.

Mhiyar Sepahan Company fully meets the needs of its customers in this field by producing high-quality and affordable Iraqi towers.

To contact us:

For more information about Mhiyar Sepahan Company’s products and to receive a free consultation, please contact our experts.