Steel water transmission pipe by spiral method (spiral welding seam)

Content list

Water transmission pipes or seamed spiral pipes are produced in Mahyar Profile Sepahan Company with a nominal capacity of 250,000 tons per year for use in the supply chain of water, oil and gas, as well as pipe exports to neighboring countries.

Technical Specifications of Mehyar Profil sepahan Spiral Pipes:

- Diameter: Up to 100 inches (2540 mm)

- Thickness: Up to 1 inch (25.4 mm)

- Steel Grade: Up to API-X80

- Welding Method: Dual Offline

- Advantages of Dual Offline Welding:

- Higher quality and production capacity

- Precise and defect-free welding

- Increased pipe strength and resistance

- Reduction of internal stresses

- Longer pipe life

Applications of Mehyar Profil sepahan Spiral Pipes:

- Water Transmission: Pipelines for drinking water, sewage, irrigation, and drainage

- Oil and Gas Transmission: Pipelines for crude oil, natural gas, and oil and gas products

- Construction Industry: Concrete piles, metal skeletons, bridge supports

- Marine Industries: Oil and gas platforms, docks, breakwaters

Advantages of Using Mehyar Profil Sepahan Spiral Pipes:

- High Quality: Use of high-quality raw materials and advanced equipment in the production process

- High Strength: Excellent strength and resistance to pressure and corrosion

- Long Service Life: Longer lifespan compared to straight-welded pipes

- Flexibility: High flexibility and possibility of bending at different angles

- Perfect Sealing: No leaks or loss of fluid

- Reasonable Price: Competitive and affordable price

Advantages and Benefits of Spiral Welded Steel Water Transmission Pipes

Advantages of Spiral Pipes:

High Strength and Durability:

- Spiral pipes, due to their helical structure, offer high strength and resistance to pressure and corrosion.

- These pipes can perform well in harsh and demanding conditions, such as earthquake-prone areas or with corrosive soils.

Long Service Life:

- Spiral pipes have a longer lifespan compared to straight-welded pipes due to the high quality of welding and the absence of weld defects.

- The long life of these pipes translates to reduced maintenance and repair costs over time.

Flexibility:

- Due to their helical structure, spiral pipes are highly flexible and can be bent at various angles.

- This flexibility simplifies the installation and commissioning of pipes and allows for their use in complex routes.

Perfect Sealing:

- Spiral pipes, thanks to precise and flawless welding, provide a complete seal, preventing any leaks or fluid loss.

- This perfect seal prevents environmental pollution and resource waste.

Reasonable Price:

- Despite their numerous advantages, spiral pipes come at a reasonable and cost-effective price.

- This affordable price makes spiral pipes an economical choice for water transmission.

Other Advantages:

- Variety in thickness and diameter

- Capability of production in long lengths

- Easy installation and commissioning

- Abrasion resistance

- Easy transportability

Applications of Spiral Pipes:

- Drinking water pipelines

- Wastewater pipelines

- Irrigation and drainage pipelines

- Oil and gas pipelines

- Concrete piles

- Metal skeletons

- Bridge supports

- Oil and gas platforms

- Docks

- Breakwaters

Comparison of Spiral Steel Water Transmission Pipes with Similar Products

Spiral steel water transmission pipes (also known as spiral-welded or helical-welded pipes) offer several advantages over other similar products, such as straight-welded pipes, galvanized pipes, and polyethylene pipes. These advantages include:

Strength and Durability:

- Spiral pipes have higher strength and resistance to pressure and corrosion due to their helical structure.

- They can perform well in harsh and demanding conditions, such as earthquake-prone areas or corrosive soils.

- Straight-welded pipes are weaker against pressure and corrosion due to the presence of a weld seam, and are more prone to leaks.

- Galvanized pipes are resistant to corrosion but not as strong as spiral pipes.

- Polyethylene pipes are flexible but not as strong as steel pipes and have lower resistance to high temperatures.

Longevity:

- Spiral pipes have a longer lifespan than straight-welded pipes due to the high quality of welding and the absence of weld defects.

- This means lower maintenance and repair costs over time.

- Straight-welded pipes have a shorter lifespan due to the weld seam and are more prone to leaks.

- Galvanized and polyethylene pipes have a long lifespan but not as long as spiral pipes.

Flexibility:

- Spiral pipes are highly flexible due to their helical structure and can be bent at various angles.

- This simplifies installation and commissioning and allows for use in complex routes.

- Straight-welded pipes are less flexible and more difficult to bend.

- Galvanized pipes have low flexibility, and bending can damage them.

- Polyethylene pipes are flexible but not as strong as steel pipes.

Sealing:

- Spiral pipes have a perfect seal due to precise and flawless welding, preventing any leaks or fluid loss.

- This prevents environmental pollution and resource waste.

- Straight-welded pipes are more prone to leaks due to the weld seam.

- Galvanized and polyethylene pipes have a good seal but not as perfect as spiral pipes.

Price:

- Spiral pipes, despite their numerous advantages, have a reasonable and cost-effective price.

- This makes them an economical choice for water transmission.

- Straight-welded pipes are cheaper but have lower quality and lifespan than spiral pipes.

- Galvanized and polyethylene pipes are more expensive.

Longitudinal Production:

- Spiral pipes can be produced in long lengths, reducing the number of joints and seams in the pipeline, benefiting the sealing and strength of the pipeline.

- Straight-welded pipes are usually produced in shorter lengths.

- Galvanized and polyethylene pipes can also be produced in long lengths but are not as strong as spiral pipes.

Abrasion Resistance:

- Spiral pipes have high abrasion resistance due to their increased thickness and helical structure.

- This makes them an ideal choice for conveying corrosive materials such as wastewater and slurry.

- Straight-welded pipes have lower abrasion resistance.

- Galvanized and polyethylene pipes have some abrasion resistance but not as much as spiral pipes.

Transportability:

- Spiral pipes are easier to transport due to their flexibility.

- They can be transported in rolls, saving transportation space and costs.

- Straight-welded pipes are easier to transport due to their shorter length.

- Galvanized and polyethylene pipes are easier to transport due to their flexibility but not as strong as spiral pipes.

Overall, spiral steel water transmission pipes offer a combination of strength, durability, flexibility, sealing, affordability, and long production lengths, making them a superior choice for various water transmission applications.

The method of transportation of water transfer pipes

quality guarantee

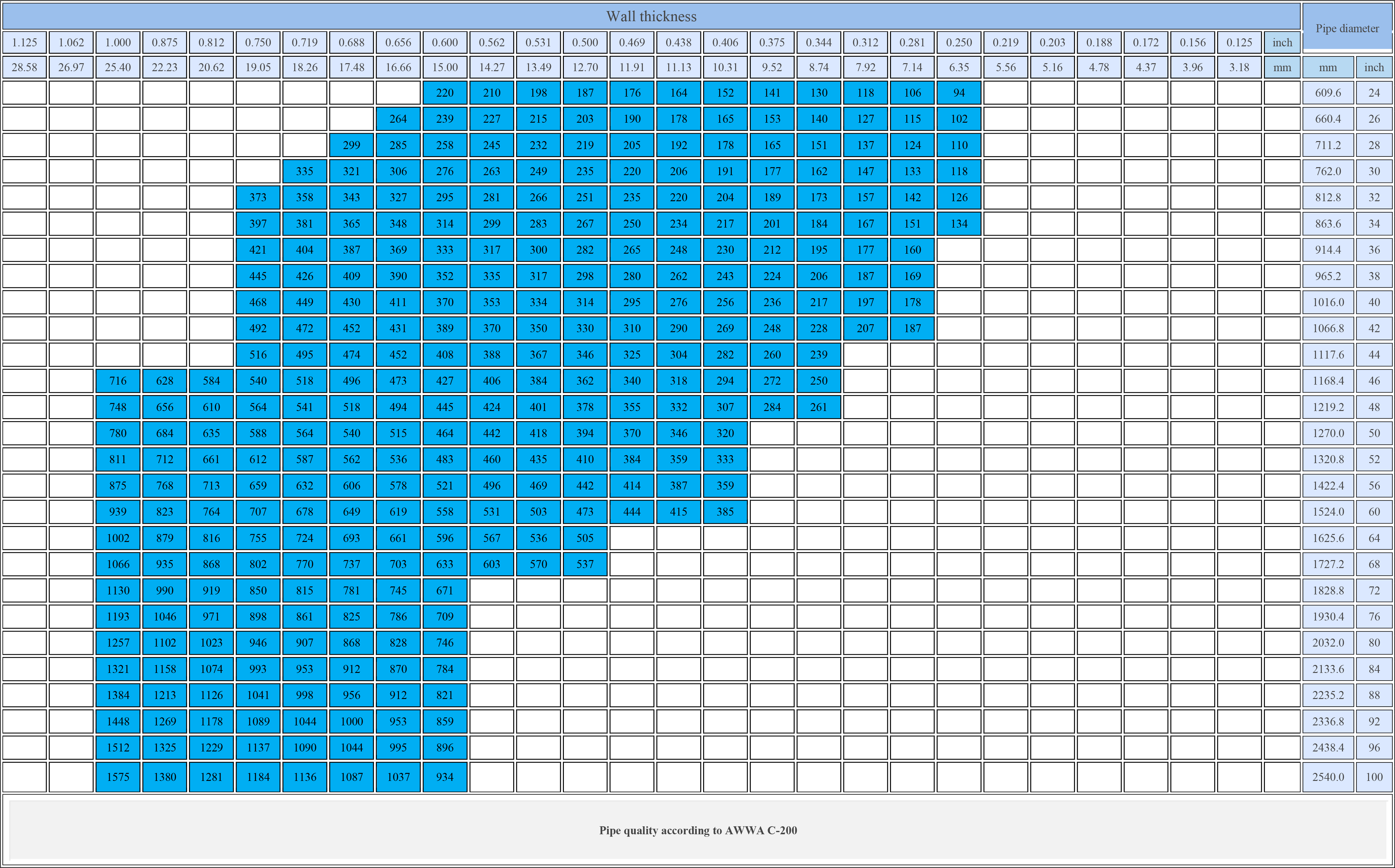

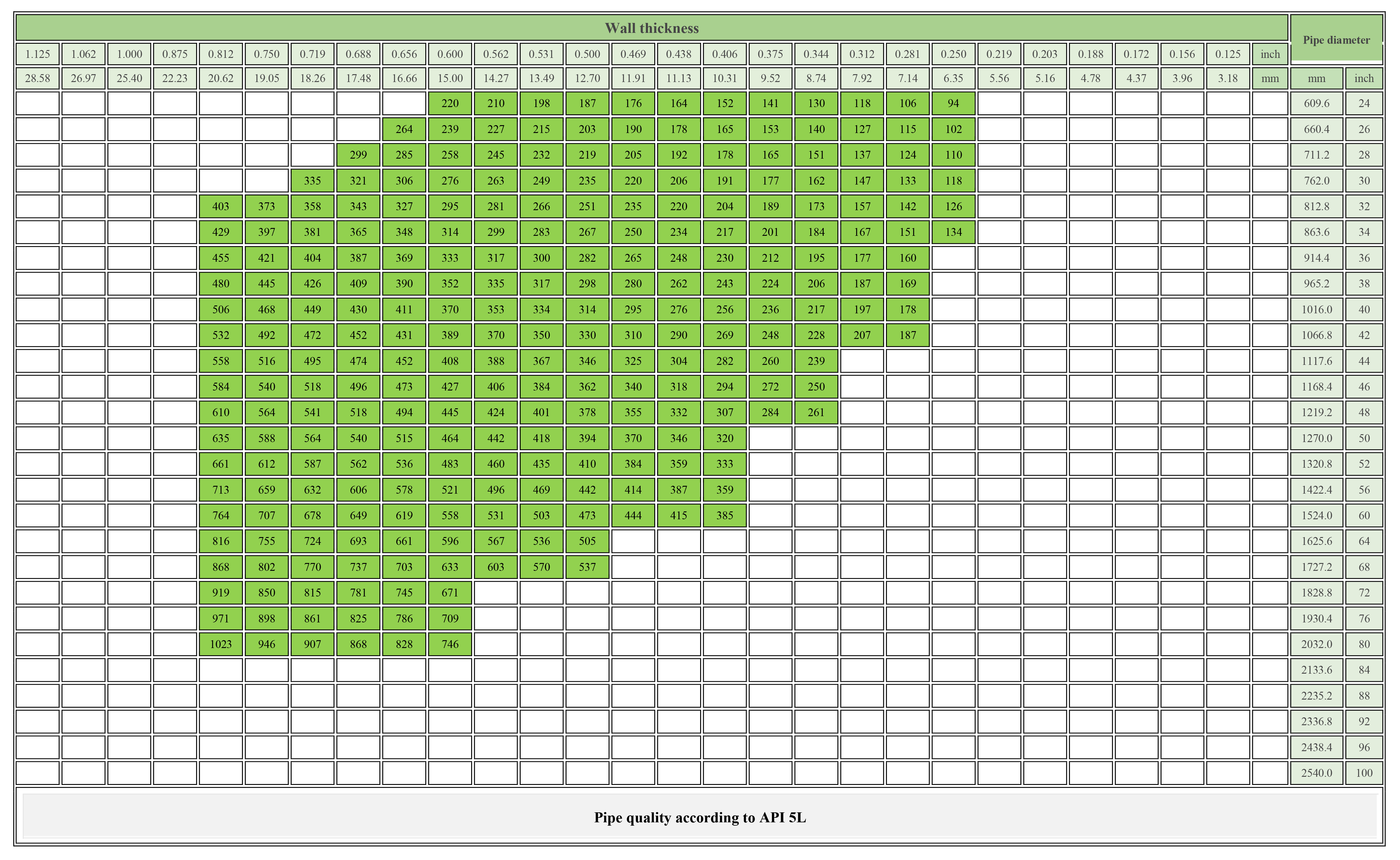

The quality of our products is guaranteed by the modern and pre-tested methods with using the advanced equipment according to approved process flow and world-recognized standards such as API, AWWA, and NACE. All the products are delivered to the clients with the related quality certifications.The matrix of water and pile consumption

Matrix of oil, gas and petrochemical consumption

About Mehyar Profile Sepahan Company

Mehyar Profile Sepahan Company was established in 2016 with the aim of producing spiral steel water transmission pipes. The company, by utilizing modern machinery and equipment as well as experienced specialists, has managed to become one of the leading manufacturers in this field.

Mehyar Profile Sepahan, with its commitment to quality and customer satisfaction, is always striving to provide the best products and services to its customers.

Certificates and Honors:

- ISO 9001:2015 Certificate

- ISO 14001:2015 Certificate

- OHSAS 18001:2007 Certificate

- Receiving a statuette and plaque of honor from the Iranian Pipe and Fittings Industry Association

- Selected as an exemplary industrial unit in 2019

Customers:

Mehyar Profile Sepahan Company, with a history of cooperation with reputable companies in various fields, is proud to be recognized as a reliable supplier.

Some of the company’s clients include:

- National Iranian Oil Company

- National Iranian Gas Company

- Water and Wastewater Company of Iran

- Ministry of Roads and Urban Development

- Ports and Maritime Organization

Vision:

Mehyar Profile Sepahan Company, with the vision of becoming one of the largest producers of spiral steel water transmission pipes in the Middle East region, is striving to increase its share in domestic and foreign markets by increasing production capacity, product diversification, and quality improvement.

Some of the company’s programs to achieve this vision include:

- Increasing production capacity to 500 thousand tons per year

- Expanding the product portfolio and producing pipes with larger diameters and thicknesses

- Exporting products to neighboring countries and the region

- Upgrading the level of technical knowledge and expertise of employees

- Implementation of modern quality management systems

- Increasing customer satisfaction

Mission:

Mehyar Profile Sepahan Company considers its mission to be the production of high-quality and affordable spiral steel water transmission pipes. The company, with its commitment to environmental protection and optimal use of resources, is striving to play its part in the sustainable development of the country.

The core values of Mehyar Profile Sepahan Company are:

- Quality

- Customer focus

- Innovation

- Commitment

- Teamwork

- Social responsibility