What is galvanized pipe?

Content list

Galvanized pipe is one of the most used pipes in the industry. This type of pipe is made of metals that are vulnerable to corrosion. For this reason, at the time of production, a coating of another metal is placed on them, which is resistant to corrosion. In fact, with this coating, the metal pipe is protected against corrosion, which is done through galvanization. For this reason, this tool is called galvanized pipes.

Therefore, it can be said that it is a steel pipe whose surface is covered with a metal layer, which is generally zinc and iron, to be resistant to corrosion. Increasing the resistance of this pipe model against corrosion and minerals increases its lifespan. These features made this pipe to be used as the most common water transfer pipe. Galvanized pipes are divided into two categories, galvanized steel and iron, based on the material.

Galvanized iron pipe

One of the most interesting features of this tube is its color recognition. The color of this tool is gray and dark and usually buyers identify and buy it through its color. This pipe is produced from white rolled iron and includes two types of light and medium. Another feature of this pipe model is its seams, which are connected through welding machines. For this reason, this pipe model is called spiral tubes.

Galvanized steel pipe

This type of pipe, which is more common in Iran, is produced from mild steel. In this way, first it is passed through the mold and with pressure, and then it is placed in the zinc plating bath, or galvanized, to increase its resistance against metal corrosion factors. This pipe is also seamed like the iron pipe. with the difference that it is more shiny and lighter than the iron type. Of course, the resistance of this pipe against acids is lower than iron pipe.

Galvanized Iron vs. Galvanized Steel Pipes:

Choosing between galvanized iron and steel pipes can be challenging. Both types of pipes have their own advantages and disadvantages that should be considered before making a purchase.

Key Differences:

Material: Galvanized iron pipes are made from wrought iron, while galvanized steel pipes are made from rolled steel.

Weight: Galvanized iron pipes are generally heavier than galvanized steel pipes of the same diameter.

Strength: Galvanized steel pipes are generally stronger and more durable than galvanized iron pipes.

Corrosion Resistance: Both types of pipes are protected with a galvanized coating, but galvanized steel pipes are less resistant to acids.

Price: Galvanized iron pipes are generally less expensive than galvanized steel pipes.

Applications:

Galvanized Iron Pipes: Suitable for general applications such as water, sewage, and HVAC piping.

Galvanized Steel Pipes: Suitable for heavier applications such as water transmission lines, steam pipes, and structural steel.

The following table provides a summary of the key differences between galvanized iron and steel pipes:

| Feature | Galvanized Iron Pipe | Galvanized Steel Pipe |

|---|---|---|

| Material | Wrought Iron | Steel |

| Weight | Heavier | Lighter |

| Strength | Weaker | Stronger |

| Corrosion Resistance | High (except against acids) | High (except against acids) |

| Price | Less Expensive | More Expensive |

Galvanized Pipes: Features and Benefits

Introduction:

Galvanized pipes are widely used for transporting water, chemicals, and waste due to their versatility and durability. They are made from either steel or iron and undergo a galvanization process that coats them with a protective layer of zinc. This coating prevents rust and corrosion, making them ideal for a variety of applications.

Features:

Versatility: Galvanized pipes are available in two types: welded and seamless. Welded pipes are made from hot-rolled sheets and welded together, while seamless pipes are produced through rolling and drawing processes.

Sizes and Dimensions: Galvanized pipes typically come in 6-meter lengths and have diameters ranging from 1 to 8 inches.

Material: The primary materials used for manufacturing galvanized pipes are wrought iron or mild steel.

Strength and Longevity: The galvanization process provides galvanized pipes with superior resistance to corrosion, significantly increasing their lifespan compared to other types of pipes. The estimated lifespan of galvanized pipes is around 50 years.

Integrity and Strength: The seamless structure of galvanized pipes enhances their strength and resistance to impact.

Appearance: Initially, galvanized pipes have a shiny appearance before installation. However, over time, their color changes to a duller shade.

Recyclability: One of the key features of galvanized pipes is their recyclability. They can be melted in thermal furnaces and reused to create new products.

Benefits:

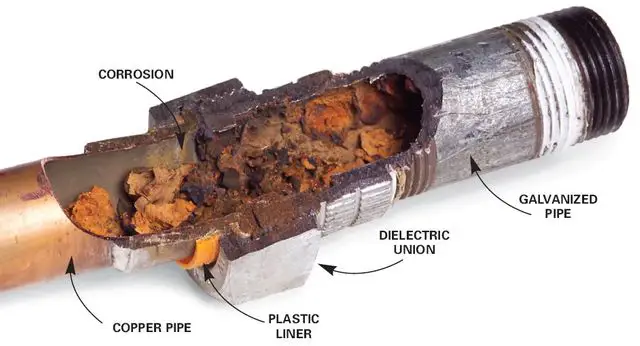

Corrosion Resistance: The zinc coating protects the pipes from rust and corrosion, extending their lifespan and reducing maintenance costs.

Durability: Galvanized pipes are highly durable and can withstand harsh environmental conditions, making them suitable for both indoor and outdoor applications.

Strength: The seamless structure and high-quality materials used in their construction make galvanized pipes incredibly strong and resistant to damage.

Versatility: The availability of different types, sizes, and materials allows for a wide range of applications, including water supply, sewage systems, electrical conduits, and structural support.

Cost-effectiveness: Although the initial cost of galvanized pipes may be higher than other types of pipes, their long lifespan and low maintenance requirements make them a cost-effective choice in the long run.

Advantages of Using Galvanized Pipes:

Corrosion Resistance:

The most significant advantage of galvanized pipes is their superior resistance to corrosion and rust. This is attributed to the zinc coating applied to the pipe, which protects it from moisture, chemicals, and other corrosive elements.

Extended Lifespan:

Due to their corrosion resistance, galvanized pipes have a considerably longer lifespan than regular steel pipes. This can lead to long-term cost savings as the need for frequent pipe replacement is reduced.

High Mechanical Strength:

Galvanized pipes possess high mechanical strength and durability. This makes them suitable for applications requiring high pressure and impact resistance, such as water and sewage plumbing systems.

Recyclability:

Galvanized pipes are recyclable, contributing to environmental conservation and waste reduction.

Abrasion Resistance:

Galvanized pipes are also resistant to abrasion, making them ideal for applications involving high-velocity fluid flows, such as water and sewage transmission lines.

Ease of Installation:

Galvanized pipes are easy to install, which can help reduce the costs associated with installation and commissioning of piping systems.

Versatile Applications:

Galvanized pipes find application in a wide range of areas, including water and sewage plumbing systems, heating and ventilation systems, water and sewage transmission lines, structural steel construction, and industrial fencing.

Additional Benefits:

Low Maintenance: The zinc coating minimizes the need for regular maintenance, reducing operational costs.

Smooth Surface: The smooth inner surface of galvanized pipes reduces friction and improves flow efficiency, leading to lower energy consumption.

Aesthetics: Galvanized pipes offer a visually appealing appearance, making them suitable for exposed applications.

Applications of this type of pipe

According to the above, we found that the best pipes for water and gas transmission are metal and steel models. Since galvanized pipes are produced from steel sheets with a metal top, they are usually used to transfer fluids such as gas and water as well as heat. Due to this issue, this type of pipe is used in various industries and has various applications, which include:

- as water transfer pipe and water supply for construction industry

- In the field of irrigation systems

- Refineries

- Ventilation systems

In general, these pipes are divided into different types based on consumption, such as water pipes, electricity pipes, water wells, greenhouses, fences, greenhouse structures, carpet cleaners, fences, and fence bases.

Types based on production method

These tools are also classified based on the manufacturing method, which includes hot and cold types:- Cold galvanized:The method of making this type of pipe is such that it makes their surface shiny. Also, this tool has surface coating. so that if it gets a deep scratch, the underlying layers will be oxidized. Therefore, its resistance and strength are less compared to other models. The resistance of this type of pipe is so low that by dragging a metal object on its surface, it gets scratched and hit. These features made this method of galvanizing to be used in automotive, parts making, bolt and nut industries, and health industries.

- Hot galvanized: The method of making this tool has caused its resistance to be much higher compared to the cold type. so that its useful life is between 25 and 30 years. Among the other features of this product, we can mention the dull gray color, smooth and uniform surface, and galvanized thickness of 40 to 120 microns. Due to these characteristics, this manufacturing method is used in iron pipes, which are usually used in open and external environments. Among the applications of this method are telecommunication towers, high voltage power towers, power poles and Road Guardrail pointed out.

in the article Comparison of hot and cold galvanized pipe These two construction methods have been fully investigated.

The price of galvanized pipes

The price of this tool varies according to the material, manufacturing method and type of application. In addition, factors such as weight, square footage, internal diameter size and thickness also affect the price of this product. Another feature of this product is that it is divided into 3 types of light, medium and heavy based on weight. Therefore, in addition to the material and size of the inner diameter, the weight also affects the final price of this product. In general, the types of factors affecting the price of this tool are:

| Inner diameter size | Thickness | The weight of each branch is 6 meters |

| 60×60 inch box | 2 inches | 6/24 |

| 70×70 inch box | 2 inches | 28 |

| 70×70 inch box | 2/20 inch | 29 |

| 60×60 inch box | 2 inches | 6/24 |

| 60×60 inch box | 2 inches | 6/24 |

| 60×60 inch box | 2 inches | 6/24 |

Why should you cooperate with us?

- More than 30 years of experience

- Nominal capacity of 250 thousand tons

- Using the best steel alloy with API-X80 grade

- Continuous expansion and presence in domestic and foreign markets

- Product quality test statistics at the highest possible level

Frequently Asked Questions

It is a type of steel and metal pipe that is resistant to all kinds of corrosion factors due to the galvanization operation on it, and for this reason, it has a long life..

These pipes are divided based on various factors such as material and manufacturing method. In this way, the types of galvanized pipes include iron and steel types based on the material, and hot and cold types based on the manufacturing method.

The price of this tool varies according to the material, manufacturing method and type of application. In addition, factors such as weight, square footage, internal diameter size and thickness also affect the price of this product.