As this type of pipe was defined in detail on the galvanized pipe page, we realized that this type of pipe is produced in two hot and cold methods, and we are going to discuss the similarities and differences, advantages and disadvantages of these two methods in this article. Let’s examine.

Resistance

Content list

The first and most important indicator in the investigation of these two methods is the resistance of the pipe, the resistance of hot galvanizing can be said to be ten times higher than that of cold galvanizing due to the processes that are carried out.

Construction method

The second indicator is their manufacturing method, in the galvanizing method, the plating process of pipes is obtained between 450 and 480 degrees Celsius, and this is obtained in the case of cold galvanizing at room temperature.

The amount of adhesion

The third indicator is the degree of adhesion, because the steel core and zinc (zinc) of cold galvanized pipes are separate and the top layer (zinc) that is on the pipes is thin, it is easily destroyed, and as a result, the degree of adhesion of cold steel pipe is very high. It is less hot than galvanized steel pipe.

The amount of thickness

The fourth indicator is the thickness of the galvanized layer, which means that the zinc thickness in the hot galvanized layer is about 50 grams to a maximum of 600 grams per square meter, while the zinc thickness in the cold galvanized layer is 15 grams per square meter. (for special works, up to 100 grams per square meter).

Useful life

The fifth indicator is the useful life of these pipes, the useful life of these 2 types of pipes is different depending on the type of use they are made of; For example, the useful life of a hot galvanized pipe is normally 30 years, but if you want to use this pipe in a greenhouse environment, which is a place with high humidity, its life is limited to almost 5 years, in such a situation, the useful life of cold galvanized pipes Finally, it is 3 years.

Price

The sixth indicator is the price of hot galvanized pipe versus cold galvanized pipe, considering that the production method and the amount of zinc used in hot galvanized pipe has a higher price than the cold galvanized method, but you should know that the amount of hot galvanized is used. It is more because it can be used in environments exposed to moisture and even in acidic and corrosive environments.

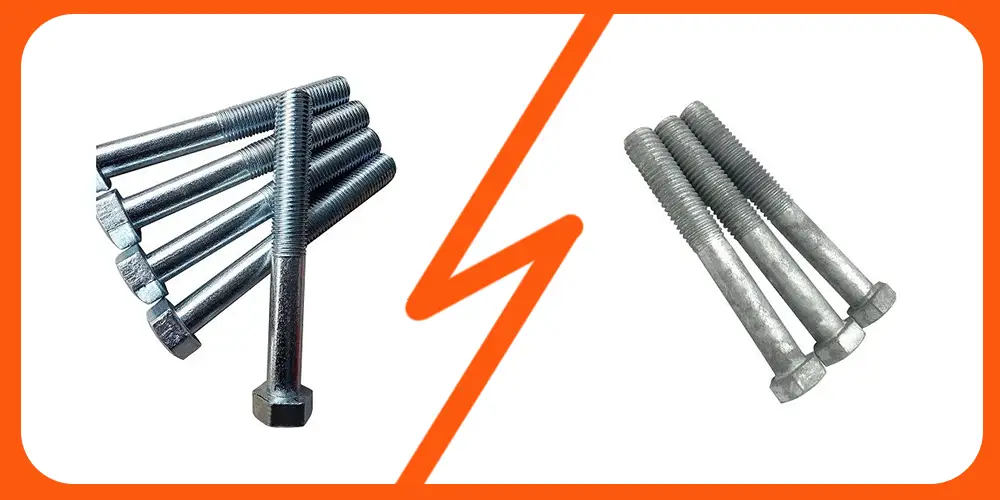

Application

According to the mentioned cases, cold galvanizing is usually used in the automotive industry, parts making, bolts and nuts, and sanitary industries, and hot galvanized pipe is used in open environments, which is used in the construction of power transmission bases and road guardrails. Takes.

Conclusion

According to the production method of hot galvanized pipe, we realized that the resistance, adhesiveness, useful life of this type of pipe is more than the second method, which has a higher price, and finally, according to the type of project, cost and environment that is supposed to be used. If galvanized pipe is used, you should purchase one of these two pipe models.